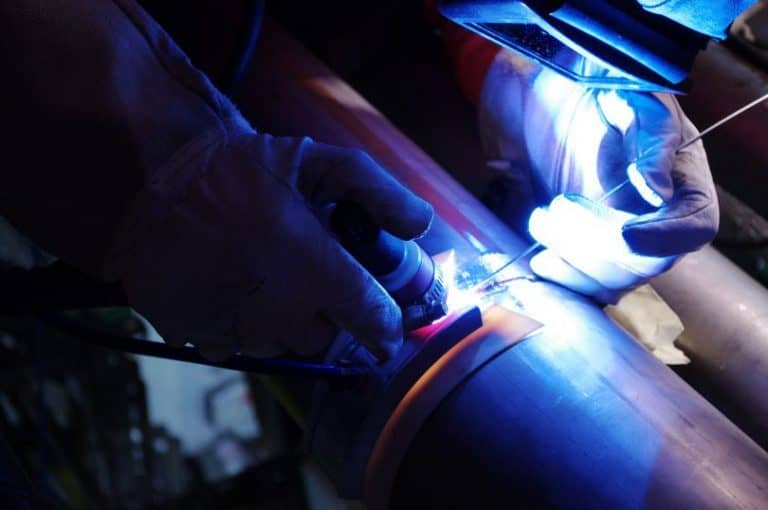

As a novice in the welding trade, you may, from time to time, hear your colleagues speak about different AC vs DC welding and what’s best to apply them when having some problems with welding. They will often talk about machines that can work on both direct and alternating current.

What to use? Which is better, AC or DC?

This is a frequently asked question in the workplace or on welding forums and is must-know knowledge when buying a TIG Welder (especially the more expensive ones). So, here is all that you need to know about AC vs DC Welding. Not to mention a few things that you don’t need to know but will help you better grasp the full picture

Key Takeaways

- Is it better to weld with AC or DC?

The answer will solely depend on your welding applications. You can use DC welding to weld steel with any common welding process (MIG/Flux Core, TIG, Stick). However, to weld aluminum, you will need to switch to AC TIG, and if there is an arc blow, switch to AC Stick.

- What is the difference between AC and DC welding?

AC welding causes more weld spatter, less stable arc, and somewhat medium penetration, but it results in cleaner welds and limited heat when welding aluminum and delicate metals. DC welding takes nearly 85% of all welding as it offers great penetration, less spatter, and smooth weld arc in welding steel, but you cannot weld exotic metals without contamination and burn through.

- What is the advantage of AC/DC Welder?

With an AC/DC welder, you can easily switch between AC and DC currents. As a result, you combine good sides of both, and you can weld nearly all metals.

- Is AC or DC Welding safer?

While both currents can be hazardous, AC is four to five times more dangerous than DC due to the frequency of 50-60 Hz. The AC current oscillates in the body, causing contractions and severe damage to muscles and organs, including the heart.

Differences between AC/DC Currents

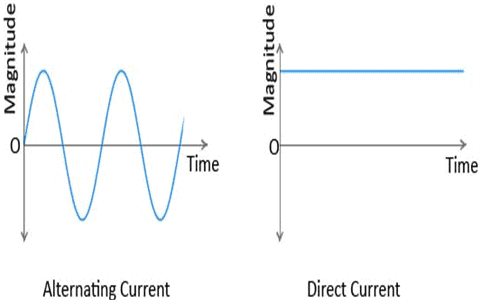

AC and DC are different types of electrical current or voltage (V) used for the conduction and transmission of electrical energy all over the world. And what is electrical current?

It is the flow of charged particles, the electrons. And the difference between these two is in their flow. The DC flows in a single direction, while AC, as the name states, alternates constantly from positive to negative and back again.

DC in Welding

When it comes to welding, most high-end machines utilize DC current to ensure stable arc or have the ability to change from DC to AC welding, like some professional TIG welders.

Many metals and metal alloys, except aluminum and magnesium, can be welded with DC welders. DC welding machines are especially useful when DC arc welding higher strength and low alloy steels. Direct current is the only way to do it.

MIG welders, to my knowledge, can’t run AC welding except for some inexpensive ones called “buzz boxes”. There is no decent MIG welder out there that can perform well on AC. Some glassless flux core welders can give you a decent bead, but then again, it will be low penetration and with a lot of spatter compared to a DC welder.

DC is mainly used for low voltage applications, electronics, circuit boards, solar panels also like one in your welding helmet, and of course, welding. Furthermore, DC is used for all types of welding, around 85% more than AC welding.

However, understanding how dc current flows will help you understand pros and cons of dc welding.

What is DC? (Brief Explanation)

Direct current flows in one direction. It’s constant polarity flow and a one-way street from negative to positive. One pole is always negative, and the other pole is always positive. Direct current is used to refer to power systems that use only one polarity of voltage or current and to refer to the constant, zero-frequency.

A good example of DC is the simple battery that you have in your TV remote. On it, the charged particles flow from negative (-) to positive (+) until the battery discharges completely.

DC welding machines require an internal transformer, which isn’t so expensive in the machines, but it would be tremendous in the household electricity. That’s where AC current is used.

DC TIG welding

If you deal with steel or consider welding thick material occasionally, you are more than good with DC TIG welding. While the DC TIG won’t result in superior cleanliness or limited heat, you get a more stable arc with a higher welding output and deeper penetration.

One of the advantages of DC over AC TIG is the lower costs of the equipment. DC TIG welders are quite cheaper than AC/DC machines, so you won’t have to break the bank. However, most experienced welders choose TIG for its aesthetics and cleaner welds, but as a beginner, you are good with DC welding.

DC Stick Welding

Note again that most welding jobs can be done using DC output. DC negative polarity (DCEN) is called “straight polarity DC” and DC positive polarity (DCEP) “reverse polarity”. Out of the two, DC positive is much more used today.

DC equipment is cheaper, and it produces a good weld bead profile, deep penetration, and overall better weld properties, low bending, high durability, tensile strength, etc.

These suit well when welding bridges, ships, building metal construction, pipes, and root pass on pipes. Generally, welding on higher strength and low alloy steels is exclusively done with DC reverse, and it is more suitable than AC welding for vertical welding and overhead welding.

DC- (negative polarity) was once the norm for stick welding before the invention of inverter technology. Now it is used on thin sheet metal in an attempt to prevent burning through the material or in places where metal would not be exposed to extreme temperature changes or hazardous water.

What Are The Cons of DC Welding?

While DC takes nearly 85% of all welding, it still has some drawbacks. First of all, you cannot use DC welding when welding delicate metals such as aluminum. DC welder can cause weld defects when cleanliness is crucial.

In addition, with DC welding, you cannot limit the heat, as it always flows in one direction. As a result, it can cause burn-through in exotic metals. During the DC SMAW welding, arc blow issues can occur, and you can learn more about them further in the text.

AC in Welding

While many consider AC welding inferior due to its lower penetration, alternating current has its own uses with MMA (stick) and TIG welding processes.

In certain DC stick welding applications, weld metal can be magnetized, and the arc blow issue appears. Switching to AC welding machines with special AC-designated electrodes can help you deal with an issue.

When it comes to TIG, welding aluminum is impossible without AC current. Due to its properties, dirt and high heat can cause severe issues when welding aluminum. That’s where the AC welder kicks in, as you can perform TIG welding aluminum with ease or without fear of contamination or burning a hole in it.

What is AC? (Brief Explanation)

AC is completely opposite to DC. Unlike DC welding, the flow alternates constantly from positive to negative and back again, traveling in two directions (bi-directional). It makes a wave-like pattern or sinusoid. In other words, the current constantly oscillates in repletion and at a rate of sixty times per second or 60 hertz (in the US).

AC dominates the world because of its ability to efficiently distribute power over long distances. It’s used to deliver electricity to households, businesses, etc; for example, all your house lights are running on AC current.

So, what does all of this mean to welders?

AC TIG Welding

To weld delicate and non-ferrous metals, you will have to use the TIG process with capable AC welders. At this point, you realized that the electric current flow moves from positive to negative and back again many times a second.

So, when flow flips to the electrode positive portion of the AC cycle (when current flows from the base metal back to the electrode), it actually provides a “cleaning” action and the electric arc blasts of surface oxides.

Next, the alternating current flows back to the negative polarity, allowing metals to fuse properly without fear of burn-through or defects. As a result, you can use AC TIG welding to join delicate metals such as aluminum or magnesium and other non-ferrous metals.

AC TIG Welding Aluminum

Welding aluminum can be extremely challenging due to the properties of the metal itself. The aluminum has basically two layers, the base aluminum, and aluminum oxide.

The oxide is essentially formed when metal is exposed to air, and it has a much higher melting point of about 3600 degrees F, while base aluminum melts at 1200 degrees F.

That’s why you have to remove the aluminum oxide before the base metal starts to melt. Any oxide residues and layers will cause poor fusion, regardless of the welding process. On thinner metals and sheets, the base metal will overheat and liquefy before the arc can get through the oxide.

Now that’s where AC TIG welders kick in. An alternating current can basically transform the torch into a ray gun.

As the AC welding current alternates back and forth, it cleans and properly melts and fuses the aluminum base metal, making it the best way to weld aluminum. On an advanced AC TIG welding machine, you can even adjust the AC balance to improve cleaning action for even cleaner welds.

Even though AC welding is slower than DC welding, the weld quality of the joint is superb and is aesthetically pleasing.

AC Stick Welding And Arc Blow

While DC, either positive or negative, takes the most part of Stick/Arc welding, many wonder why to use AC at all. Well, often there comes the problem in stick welding, the phenomenon called the “arc blow”. It’s a huge problem that occurs no matter how good of a welder you are or how well you prepare and clean base metal.

Arc blow issues during DC welding can occur when welding magnetic materials of the welding arc or thermal properties. Depending on the current conditions, the arc can easily wander due to magnetics or lag behind the electrode due to thermal properties.

Sometimes you will be able to solve it by changing the electrode or moving a ground clamp to another place. However, if that doesn’t work, the only solution is to switch to the alternating current. AC current’s fast-altering nature successfully eliminates this problem.

Wanna see how this works in practice?

Here is a phenomenal vintage video from 1944 where the arc blow problem is perfectly shown.

Drawbacks Of AC Welding

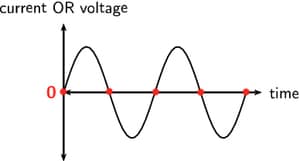

As you can see on the graph, the AC current alternates from positive to negative welding polarity. At a certain point in Stick welding, the current crosses the straight line by the middle. That line represents the zero amperage or no output.

At that moment, most of the electrodes tend to “pop out,” and the arc then extinguishes, momentarily closing the porosity in the process. It could also extinguish permanently, causing you a lot of headaches and extra work.

When it comes to other welding processes, the AC current can cause more weld spatter, and it has somewhat limited penetration.

AC vs DC Welding What Are The Differences?

AC Welding

- More weld spatter

- Less stable arc in Stick welding

- Medium deposition and preparation

- Medium penetration

- No arc blow issues

- Capable of TIG aluminum welding

- Not so viable with MIG welding/Flux core welding

- TIG welding equipment is expensive

- Stick equipment is cheaper

DC Welding

- Less weld spatter

- Stable arc in multiple processes

- High deposition rates

- High penetration

- Arc blow can occur

- It cannot be used for TIG aluminum welding

- Widely used in all welding processes when welding steel

- TIG equipment is cheaper

- Stick equipment prices are medium

AC/DC Welding Machines

After learning everything you need to know about AC/DC welding, you should understand when each type is most usable. If you still have a doubt about which one to use, AC or DC, there is a simple solution. Highly versatile AC/DC welding machines.

AC/DC machines, as their name states, can work using both AC/DC currents. As a result, you can use DC welding to deal with common steel and steel alloys, and you are perfectly fine with it.

However, once you need to weld aluminum or other delicate metal, you can quickly switch to alternating current (AC).

Most commonly, these are AC/DC TIG welders, but for even higher versatility, you can opt for AC/DC Multi-process welders. These will work fine with all your task in a small fab shop or a garage.

The only drawback of AC/DC welders is their price. While DC-only welders are more common and cheaper, you will have to spend some extra bucks for added AC capability.

Origins and The War of Current

For the whole great AC vs DC debate, we have to thank to rivaling electrical engineering geniuses. Thomas Edison, the Wizard of Menlo Park, is credited with the invention (among other things) of the light bulb.

Nikola Tesla is credited with inventing the Twentieth Century. Before long, every other city in America was running on AC.

Edison sold his remaining stock in Edison Electric Illuminating of New York and went on to other projects after apologizing to William Stanley Jr., inventor of the AC transformer. No word on whether he tried burying the hatchet with Tesla.

They met when Tesla came to America looking for work with a glowing letter of recommendation addressed to Edison. Edison hired Tesla to improve his electrical conversion models. What happened next has become a matter of he said/he said. Tesla protested that he wasn’t getting paid enough.

Edison countered that Tesla’s insistence on using AC was far too dangerous and uncontrollable. Tesla rebutted that AC was more efficient, less expensive and more reliable than DC dynamos and that Edison was only interested in royalties. Words were said, animals were electrocuted. The rivalry came to a peak at the Chicago World’s Fair in 1893.

Edison had General Electric in his corner. Tesla, meanwhile, had partnered with Westinghouse. There was a bidding war to see who would power the coming fair. Westinghouse won that battle, using Tesla’s alternating current for the cost of $399,000 compared to General Electric’s bid of $554,000. On Nov. 16, 1896, Tesla won when Buffalo was lit up using AC generated by Niagara Falls. Many other cities followed suit.

Conclusion

AC versus DC is a long-held debate. Is it better for the current flow to be unidirectional or alternating from positive to negative? In the end, DC is best for MIG welding and AC is best for TIG welding. AC is also suitable for stick welding. You will have to take some precautions. In any case, electricity is like fire and money; a wonderful servant but a terrible master. Use it wisely and you can be proud of a job well done.

If you are still in doubt, you can buy a simple AC/DC welding machine and try it on your own. Each welding process will give you different results with AC and DC welding, but I think our text was enough to understand the fundamentals.