Buying industrial ventilation equipment requires evaluating the dust collector’s capabilities, which is challenging to say the least.

What you see most often are manufacturer’s claims about construction, reliability, or how long a supplier, which doesn’t say much.

Every manufacturer says the same thing — “We are the best, trust me, bro.” Right. Well, excuse me for not being so gullible.

To make things even more complex, fabricators’ needs have changed over the past 30 years. Plant safety and productivity are constant, pressing issues no matter how you look at them. Obviously, achieving regulatory air-quality standards is crucial in achieving those goals.

However, to create an effective ventilation system you must consider a wide range of variables. The type of dust and fumes produced, the air-flow dynamics that carry the particulates and pollutants throughout a plant, the welding and cutting processes your shop performs, the number of employees, and the layout of the shop.

Why Should You Filter Welding Fumes And Dust?

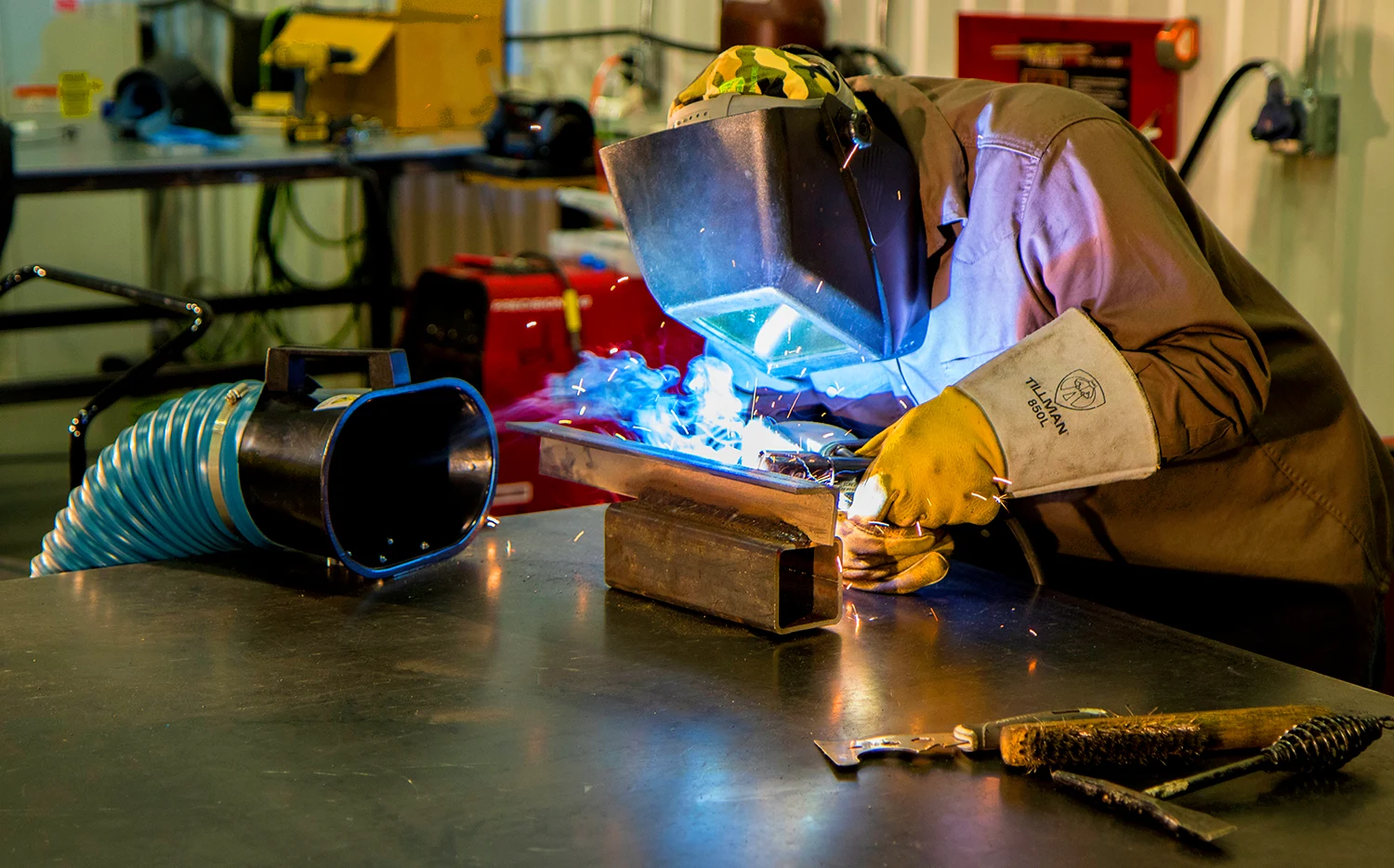

Welding fumes are a severe hazard because they cause cancer and multiple detrimental health issues. Fumes and dust created during welding contain toxic metals, silicates, fluorides, and particles from the flux used in welding electrodes.

As you can imagine, breathing the welding fumes is no fun. In fact, most of the substances contained in the welding fumes and dust are highly poisonous. So, even if you inhale some of these elements just once, you could have a bad reaction.

Working without a welding fume extractor in any bigger manufacturing facility is impossible and violates safety codes and standards.

Often, it’s necessary for welding operators to use PAPR equipment even if the welding fume extractors are present. Sometimes, welded parts are just that hazardous.

For example, welding galvanized steel, cadmium plated steels, lead, and similar toxic metal requires as much protection as you can get. So, sometimes added protection can further improve the welders’ safety.

Here are five important features for buyers to examine to ensure the right factors are considered when choosing a dust and fume collection system.

Durable And Ready To Use

A well-designed dust collector integrates all components required to make it operational (cabinet, motor, blower, control panel, safety features, and filters) into one cohesive, functional design.

The dust collector shouldn’t require much on the shop side. If everything is designed well, a simple electrical and compressed air connections are all it takes to make it run.

Too often buyers have to spec a cabinet and the mechanical components separately. This adds hours or days of labor expenses to wire and connect the individual system elements.

Engineering the proper fit and performance, compounded by this more complex installation, makes it far more expensive and challenging. Additional personnel and equipment is often needed on site, which adds costs and reduces your shop working time.

So, choosing a complete package eliminates sourcing and composing a system of individual components, and makes installation simpler and less costly.

Innovative Design Eases Installation of Fume Systems

Dust and fume collector systems that are completely assembled before shipping can be properly inspected and tested before they leave the manufacturer. So, if anything is to go wrong, they can fix it where all of their tools, skilled workers, and machinery is — the manufacturing plant.

Testing should check for leaks to ensure the integrity of a cabinet. A fully functional collector with an integrated cabinet, motor blower, and particulate containment unit is one indication of a smart design that is easier to install.

Welding Fume and Dust Extractor Control Systems

For years, the best way to improve the performance of a dust and fume collector was to find a suitable control panel that could be installed to the cabinet and allows automating of some functions.

Nowadays, many suppliers design ventilation equipment that includes an intuitive control panel to automate the entire process without having to add or install an additional control system.

A welding fume system with an integrated control panel that has a digital touch screen is clean, sleek, and far more effective. The best kind of dust and fume control systems start and stop automatically in conjunction with the welding machine. So, as soon as your operator starts welding, the welding fumes are collected.

Additionally, high-quality control systems monitor the collector’s performance continuously. This includes the blower and the filter differential pressure. Your system should have built-in diagnostic features, and track maintenance history to help maintenance staff create a safer environment and maximize the collector’s performance.

Pulse Technology For Improved Fume Filtering Efficiency

What does it take to keep a dust collector performing at peak efficiency?

Clean filters for starters.

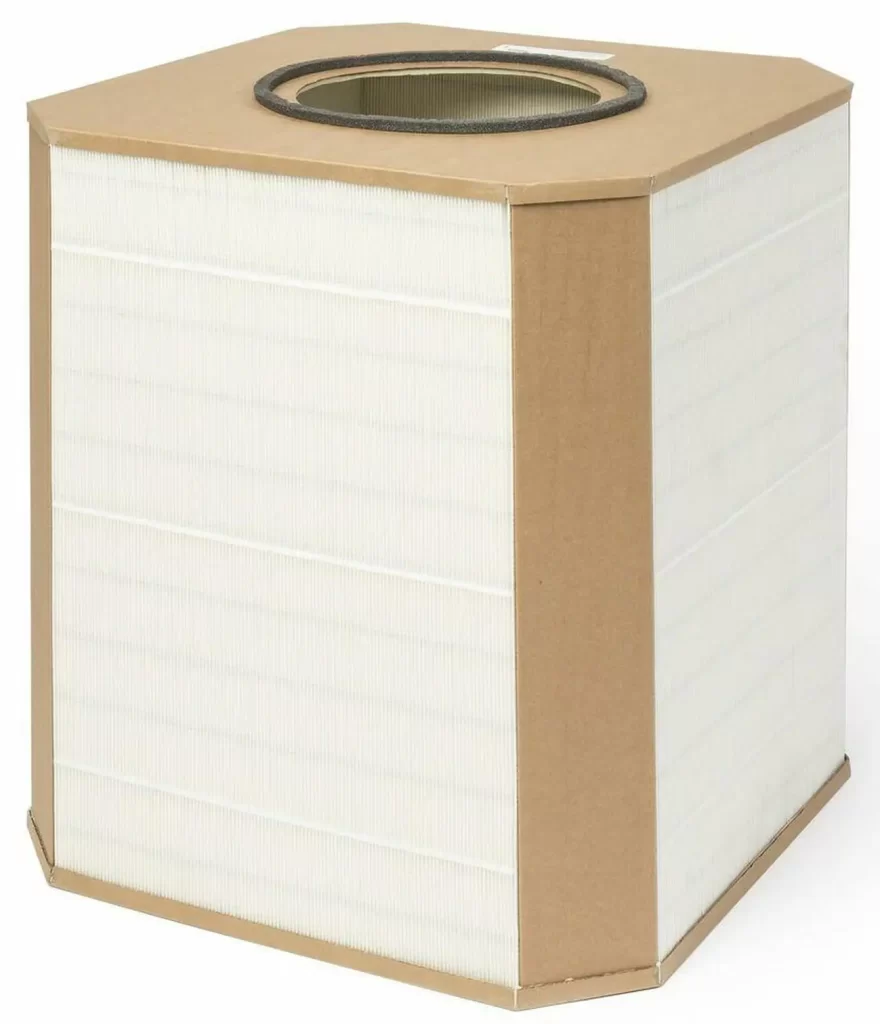

The solution to the problem of dirty filters is simple enough: Regularly shake it clean of particulates, and you can prolong the life of the filter. So, most brands provide cartridge collectors with some form of pulse-cleaning technology. Pulses disturbed the dirt and loosen it from the filter so that the particles can fall into a containment bin.

But, here’s the main issue: Shooting a pulse of air through a filter might dislodge the surface dust but it doesn’t necessarily achieve the goal. The natural tendency is for the air transporting the particulate to re-entrain, or re-deposit the particulate on adjacent filters rather than into the containment unit.

So what seems like a good idea is largely ineffective because the re-deposited dust continues to plug the filters. But, that doesn’t mean that the underlying principle is wrong.

Collectors with advanced pulse-cleaning technology use a better-engineered solution based on air-flow science. Each filter has a dedicated electronic pulse mechanism or valve programmed in sequence.

The particulate tendency to redeposit on the nearest filter is neturalized by the sequential, double-pulsed action. Even distribution of the pulse pressure through a cone or similar device ensures that the entire filter is clear from particulates, not just the top or bottom.

Filter Orientation

Filter orientation within a fume collector is also important. If the filters is in a vertical position it provides far less exposed surface area for redepositing of particulates, which extends its usable lifespan.

Welding Fume Extractor Operating Costs

The rising operating costs is an ongoing issue for everyone in the business. Filters are one of those costs that just keep on piling on expenses. Dust and welding fume collectors should have high-quality filter media to keep a plant cleaner and safer for employees. Still, this comes at a price.

But how long will those filters last? Two months? Six? A year? Can you replace the filters quickly when the time comes? The correct size and design of a system are also important to consider. If your fume collector is too small for your shop’s needs, it will consume filters rapidly.

Additionally, you need to consider the electrical power a ventilation system consumes. The best collectors minimize energy usage when they start and stop automatically, and adjust their operating speed and power in real time to match the level of activity as well as the condition and resistance of the filters.

Can you predict the collector’s performance before installation?

Guarantees are an important indication of the reliability of a collector, as well as the company that manufactured it. How long is your system covered by the manufacturer? Are you confident in a collector that is guaranteed for one year, or is five, 10 or maybe 15 years important to you?

Fume Collector Safety Mechanisms

Let’s face it, welding and cutting metal is a risky business.

But, metalworking is no different than most manufacturing processes because a certain amount of caution is required to maintain a safe manufacturing environment and protect your equipment.

Dust and welding fume collectors are often the front line of defense when it comes to air-related hazards.

There is, however, an unrecognized risk for air leaks during the dust collector’s operation. Cabinet construction is vital. Are seams and joints fully welded and engineered to create a perfect seal?

The first step is to verify that there is no leaking. The next line of defense is an integrated sensor that can detect a leak if it ever occurs and instantly shut an operation down to prevent exposure to harmful fumes and particulates.

Another important safety feature in a dust collector is an instantly-activated fire suppression system. If the particulates are accidentally ignited during welding or other operations, fire must be put out immediately.

Quality fumes and dust collectors offer a system detects the presence of smoke and heat. Usually, when smoke is detected a damper is closed to smother a fire by eliminating oxygen supply.

If heat is detected, FM-200 fire suppressant gas is deployed to extinguish the fire and protect employees, shop equipment, and the facility.

Taking your time to choose ventilation equipment for manufacturing operations can help you make the right choice. It’s important to look closely and ask questions about all available collectors. When the dust settles (pun intended), you’ll be glad you did.