Stud welding is the electric arc process that joins studs with flat workpieces using a welding arc and a pressing force. Edward “Ted” Nelson invented the stud welding process in 1939 at the Mare Island shipyard in Vallejo, California, as he wanted to speed up shipbuilding production.

The stud welding was first used to secure wood decking on submarines.

However, it was quickly adopted and used on battleships and aircraft carriers. This process is widely used in industry to infuse studs into mild steel, stainless steel, or aluminum.

Let’s overview the stud welding process, stud welding equipment, types, and advantages.

What Is Stud Welding?

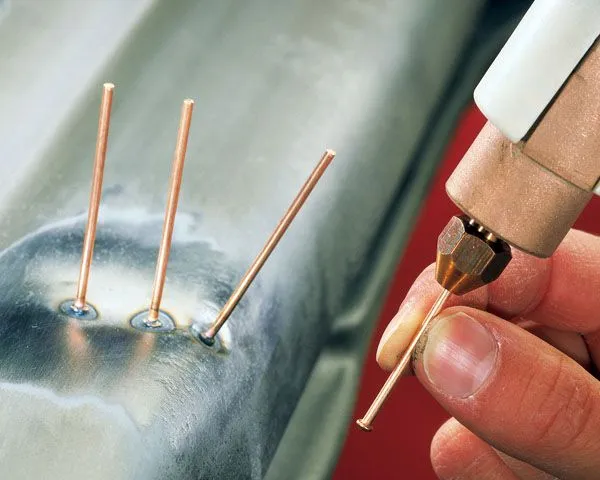

Stud welding is a process that joins a metal stud to a metal workpiece by heating both parts with an arc. A crucial difference between arc stud welding and other fastening processes is that the fastener is attached to the workpiece without marring the other side. In addition, this is one of the quickest fastening processes, as weld studs are placed within a second.

Weld studs that are used in stud welding systems can take different forms.

However, fasteners typically fall under the threaded studs, unthreaded, or tapped fasteners. The bolts may be automatically fed into the stud welder, and the whole process can be used in automated systems.

The arc stud welding method includes highly reliable fastening, and that’s why it found its way into a wide variety of industries. Arc stud welding permits strong, one-sided welds on base metals that are 0.048″ (1.2 mm) or thicker. Depending on the thickness and application, stud welding machines can complete fastening in as little as 0.06 seconds.

Types Of Stud Welding

Depending on the principle of weld studs, there are two types of stud welding. Most commonly, these are capacitor discharge stud welding and drawn arc stud welding. Capacitor discharge weld studs are used for thinner materials, while drawn arc weld studs form strong, vibration-resistant welds.

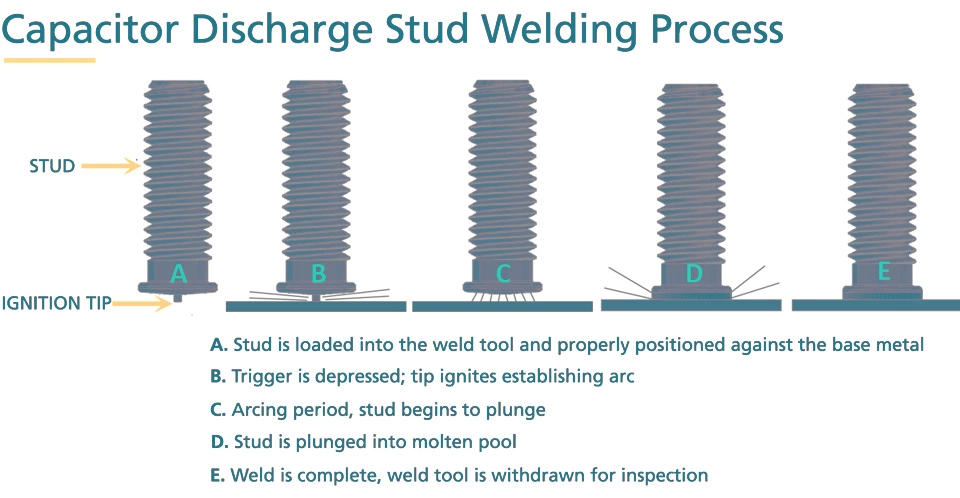

Capacitor Discharge Stud Welding

Capacitor discharge weld studs differentiate stud welding as it doesn’t require welding flux. CD welding studs require lower levels of heat and less time compared to weld than drawn arc weld studs. As a result, this method is more suitable for sheet metal and other thin materials that the drawn arc welding process would mar.

CD stud welding uses a direct-current arc from a capacitor, and a stud welding machine takes between 1 and 6 milliseconds to form a weld. The most significant advantage is that it can weld without burn-through on the opposite side of fragile metals.

CD Weld Studs

Capacitor discharge arc studs usually range from 14 ga up to 3/8″ in diameter. In addition, they have different lengths, ranging from 1/4″ to 5″ and larger. Regardless of the applications and stud welding guns, studs are usually made of mild or stainless steel, brass, aluminum, and aluminum alloys.

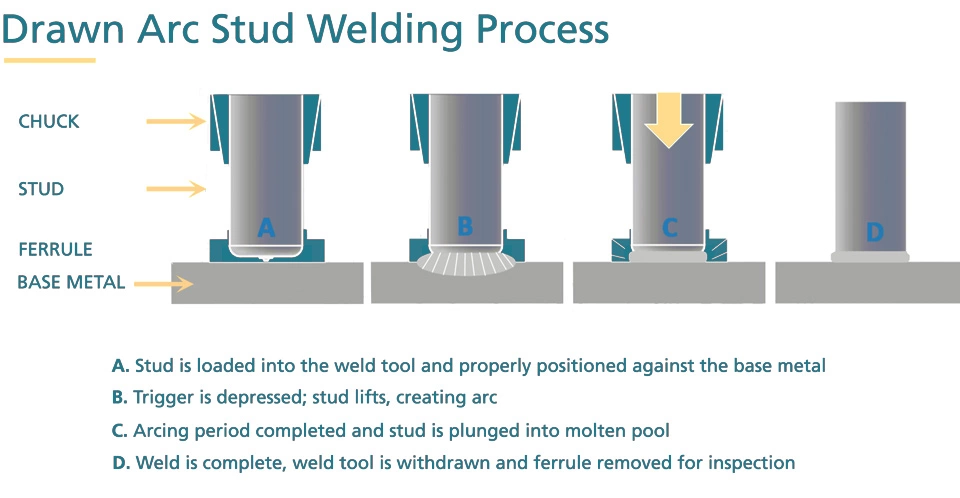

Drawn Arc Stud Welding

Drawn arc stud welding joins a stud and base metal by heating both parts with an arc. The stud is usually fastened to a flat plate by the stud and stud weld electrodes. Depending on the type of material, the polarity in stud welding changes. For example, welding aluminum would usually require a direct-current electrode positive (DCEP), while welding steel would require a direct-current electrode negative (DCEN).

Stud welding uses several welding elements, such as a flux tip and a ceramic ring. Ceramic ferrule concentrates the heat, prevents oxidation, and retains the molten metal in the weld zone.

Drawn Arc Weld Studs

Drawn arc studs come in different sizes, ranging from a #8 to 11⁄4″ in diameter. The lengths are variable from 3/8″ to 60″ (for deformed bars). Arc studs are typically loaded with an aluminum flux ball on the weld end, which aids in the welding process. As the result, weld studs form strong, vibration-resistant welds that provide a tight seal against water, oil, air, or gas leaks at the weld point.

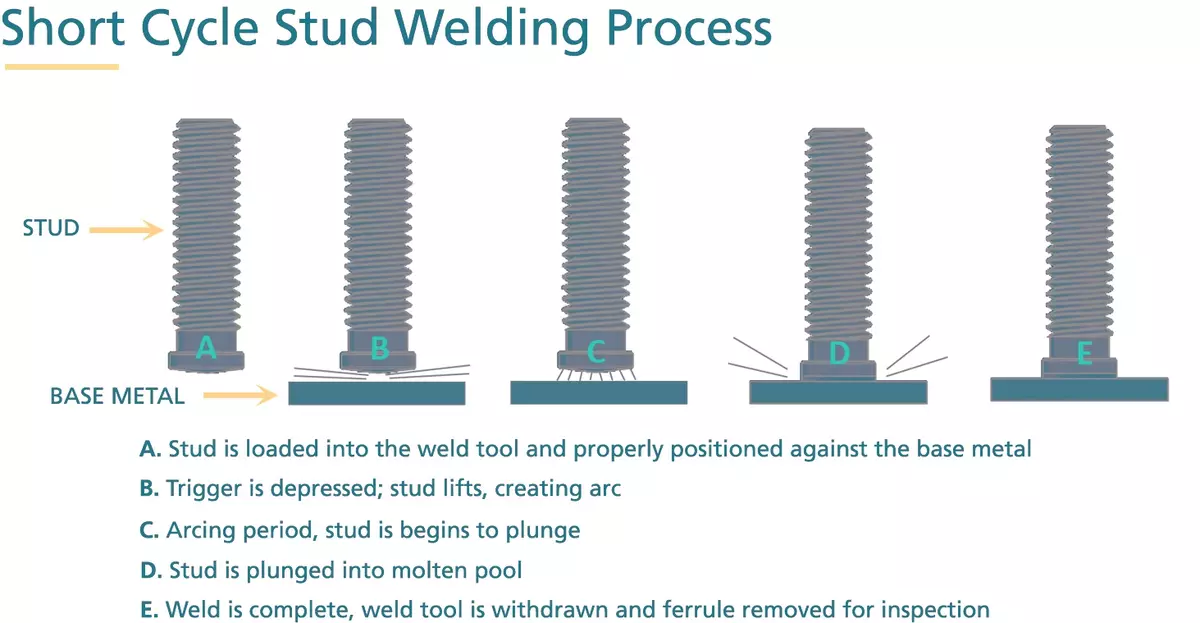

Short Arc Stud Welding

Short arc stud welding combines the good sides of both primary stud welding types. Therefore, welders can use CD welding studs within drawn arc stud welding equipment. As a result, welders can use CD welding studs to weld thinner sheet metals than the drawn arc process. However, the welds are not as strong or penetrative as with the drawn arc method, and there might be some spatter issues.

Stud Welding Equipment

Stud welding is one of the straightforward welding processes, so it is quite easy to master and perform. An entire process is highly automated, so it is commonly performed by an operator, not a “welder”. Why? Because the operator has no direct influence on the welding process. However, with a certain manual dexterity and training, the operator factor is important that the process runs smoothly.

As for the stud equipment, it consists of:

- A special (welding) power source – Stud welder that controls the system, provides welding energy and coordinates stud welding gun

- Stud welding gun or welding head

- Welding cables and connections capable of transferring the current

- Chuck for holding the stud

- Welding studs and fastener

- Technical accessories such as foot assembly for shielding gas

Automated Stud Welding

While we are usually talking about portable stud welding machines, the stud welding process can be successfully automated to perform different welding tasks. Automated stud welders can be controlled by CNC machines, as operators can set exact parameters such as arc force or pressure applied.

An extensive range of stud welding equipment and accessories are offered to solve customer-specific welding tasks. As a result, automated welding increases the speed and accuracy of manufacturing and construction work.

Portable Stud Welders

Since stud welding became popular in the automotive industry, many autobody shop owners looked for a way to get their hands on the machine. Luckily, today there are various portable stud welders you can use in your shop or a garage.

You can opt for industrial-scale stud welders that can provide an energy output of 3000 watts per second. These are aimed at professional shops, but they are still lightweight and portable, so you can move them around the workshop with ease. However, these are pricier machines, so many autobody enthusiasts opt for handheld stud welders.

These look like a simple stud welding gun, and they come as part of kits. Handheld stud welders are usually cheaper, lightweight, but capable machines. Commonly, they are rated at 1500 amps, which is more than enough for everyday autobody repair projects.

Applications and Advantages of Stud Welding

Due to the versatility of stud welding and positive results in the weld area and welded joint, it found its way into many manufacturing industries. As we noted at the beginning, the first nelson stud welding products were aimed at shipbuilding and military services.

Today, stud welding is a widely used process. It is commonly used in building bridges, buildings, and edifices but also in power distribution equipment.

Due to high-quality studs, this type of welding is used in coffee makers, griddles at fast food restaurants, salad bars, automotive, construction, agriculture, trailers, and many more.

Advantages Of Stud Welding

- Welding a 3/4” fastener takes less than one second

- It offers excellent joint strength and results

- Access to the other side of the workpiece is not required as it occurs at one side.

- The joints are vibration-proof, resist breakage, and weakening or losing

- Unlike the peripheral weld, a stud weld is a full cross-sectional we

- As a single-sided fastener, there are no indicators that a fastener is attached

- It is welded and will not work free like a press-in fastener

- It is economical since there is no through-hole penetration

- It requires little to no special skills and training to perform

Resources:

- https://www.stanleyengineeredfastening.com/en/Resources/Stud-Welding-Methods

- https://www.imageindustries.com/resources/what-is-stud-welding/

- https://hbs-info.com/wiki/stud-welding-everything-you-need-to-know?consent=false

- https://www.sunbeltstudwelding.com/what-is-stud-welding.html

- https://www.taylor-studwelding.com/about-stud-weldin