Lasers (Light Amplified by Stimulated Emission of Radiation) are today widely used in many different industries, and they found their way into the laser welding and cutting process.

While we covered laser welding in a separate article, we will discuss the laser cutting process today.

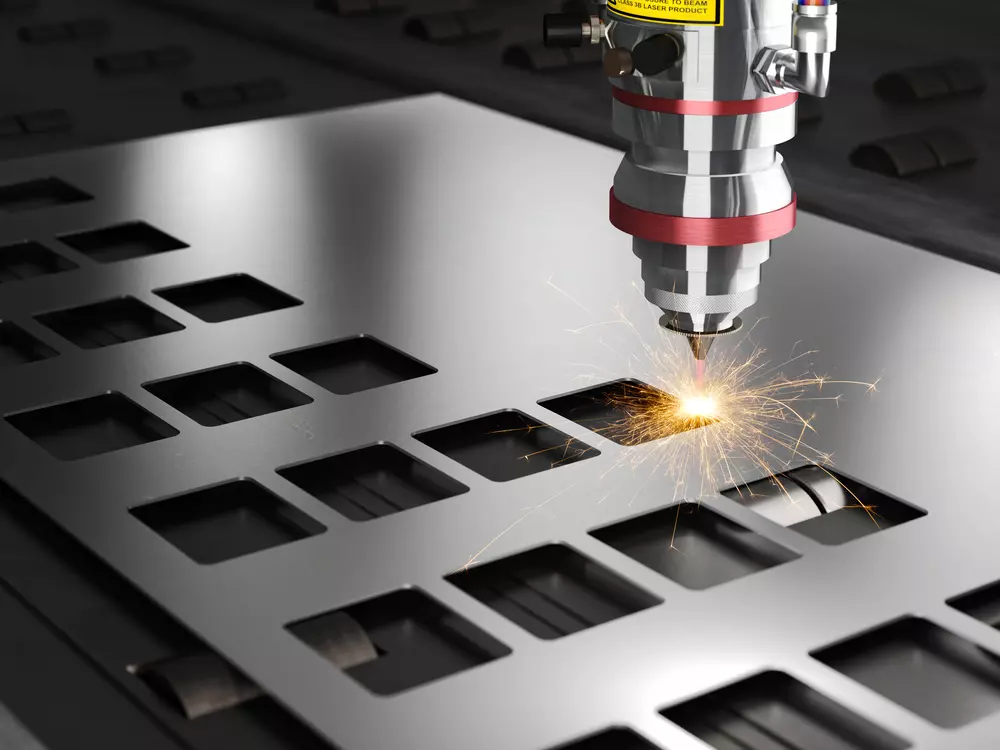

The laser cutting process utilizes a focused laser beam to evaporate and cut through metals, paper, wood, and acrylics. The most significant advantage is high accuracy and exceptional process reliability.

In this article, we will talk about the laser cutting process overview, laser cutting machines, types, capabilities, and other advantages of this cutting process.

What Is Laser Cutting? Laser Cutting Process Overview

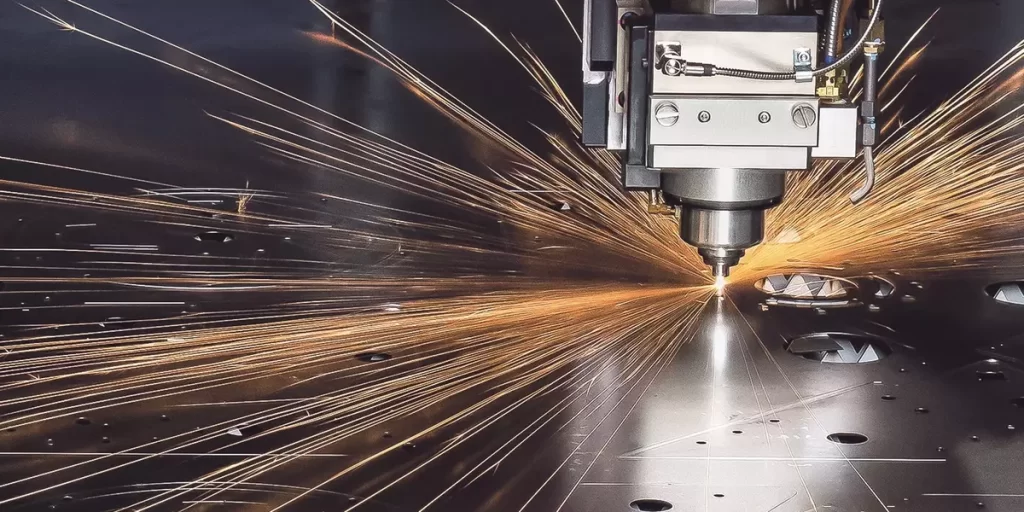

Laser cutting is a non-contact process where a precisely focused laser beam melts the selected material.

Laser optics are controlled by Computer Numerical Control (CNC), which ensures exceptional accuracy and reliability. Since there is no contact between laser cutter and cut material, there is no risk of distortion and defects, and there is no need for post-cut processing.

Laser cutting was introduced in 1965, and it was used to drill holes in diamond dies. The first application included cutting high-strength alloys and metals such as titanium for aerospace applications.

Due to the accuracy, edge squareness, and heat input control, laser cutting is slowly replacing other cutting techniques, such as plasma and oxy-fuel cutting. Today, there are significantly improved laser cutters with high laser power, which offer excellent cutting speed in thicker materials, steel plate, and wood.

Laser Cutting Methods

Fundamentally, the laser beam is used to cut the material, but there are several different laser cutting methods. These are used to cut different types of metal, and they differ in a way as they disintegrate the metal you are about to cut. Most common laser cutting processes are fusion cutting, flame cutting and remote cutting, but in specific applications, other thermal cutting processes such as stress cracking, scribing, cold cutting, and burning stabilized laser cutting are used.

- In fusion cutting, an inert gas (typically nitrogen) is used to drive out molten material out of the kerf. The material is fused by the energy of the laser beam. Nitrogen does not react with the molten material, so it doesn’t affect the energy input. This laser cutting method protects the cut metal from oxidation, and that is why it is mainly used with stainless steel, aluminum, and their alloys.

- In flame cutting, oxygen is used as the assist gas. The material is heated by laser light to combustion temperature. The medium pressure oxygen oxidizes the material and drives the slag out of the kerf. The exothermic reaction of the oxygen and material ceatesthe energy for the cutting process. However, dto economically cutis used for the economical cutting of carbon steel at very high cutting speeds.

- In remote cutting, the material is partially evaporated by a high-intensity laser beam. This method doesn’t use any assist gas, but it is commonly used for sheet metal cutting and lower material thickness.

Types of Lasers Used in Laser Cutting

Depending on the materials used to generate the laser beam, there are several types of lasers used in laser cutting. Today, most of industrial sheet metal laser cutting is done by CO2 and fiber optic lasers, while there are also Nd-YAG (Neodymium Yttrium-Aluminum-Garnet) lasers.

CO2 Lasers

The CO2 (carbon dioxide) laser is generated in a gas mixture, most commonly made of carbon dioxide (CO2), helium and nitrogen (10 – 20% carbon dioxide, 10 – 20% nitrogen, traces of hydrogen and xenon, and helium for balance.)

As a result, laser pumping is done by discharging an electrical current rather than light amplification. CO2 laser cutting machines include several type of configuration, where laser cutting head moves differently.

These lasers emit a wavelength of 10.6 µm or 9.6 µm, and they are capable of outputting decent power. The efficiency of a CO2 laser is around 30%, which makes it more efficient than other types of lasers. In addition, CO2 lasers can cut thicker materials faster than the same power fiber lasers, while producing a smoother surface finish when cutting thicker materials.

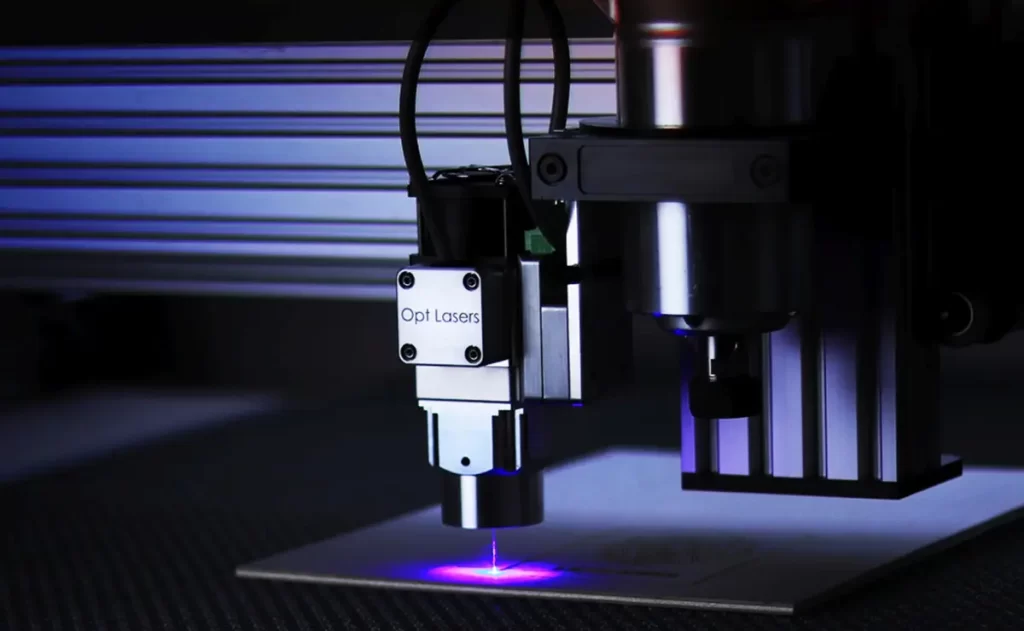

Fiber Optic Lasers

Fiber-optic lasers are the most popular types since they can generate different wavelengths for more precise cutting. With ND: YAG lasers, they are called solid-state lasers, since the beam is generated by a solid medium, compared to gas with CO2 lasers. As a result, there is an optical fiber cable made of silica glass to guide the light. The laser beam of fiber-optic lasers is straighter and smaller, making it suitable for more precise cutting.

Fiber optic lasers offer two different modes: single and multiple. Single-mode lasers produce a core diameter of between 8 µ to 9 µ, while multiple-mode lasers have diameters of 50 µ up to 100 µ. As a result, sngle-mode lasers are more efficient and produce a better quality beam of light.

Crystal lasers (Nd: YAG)

Crystal lasers use a synthetic crystal as a lasing medium, which makes them part of a solid state laser. Among these types, the most commonly used is the YAG (Y3Al5O12) crystal doped with 1% ionized neodymium (Nd3+), also known as ND: YAG laser cutting.

Within this type, laser pumping is achieved by krypton flashlamps or laser diodes.

Pumping excites the Nd ions into higher energy levels. Next, the excited Nd ions move into a lower, more stable state. This process goes on until the medium is populated with excited Nd ions. From its metastable state, the Nd ions release infrared light with a wavelength of 1064 nm.

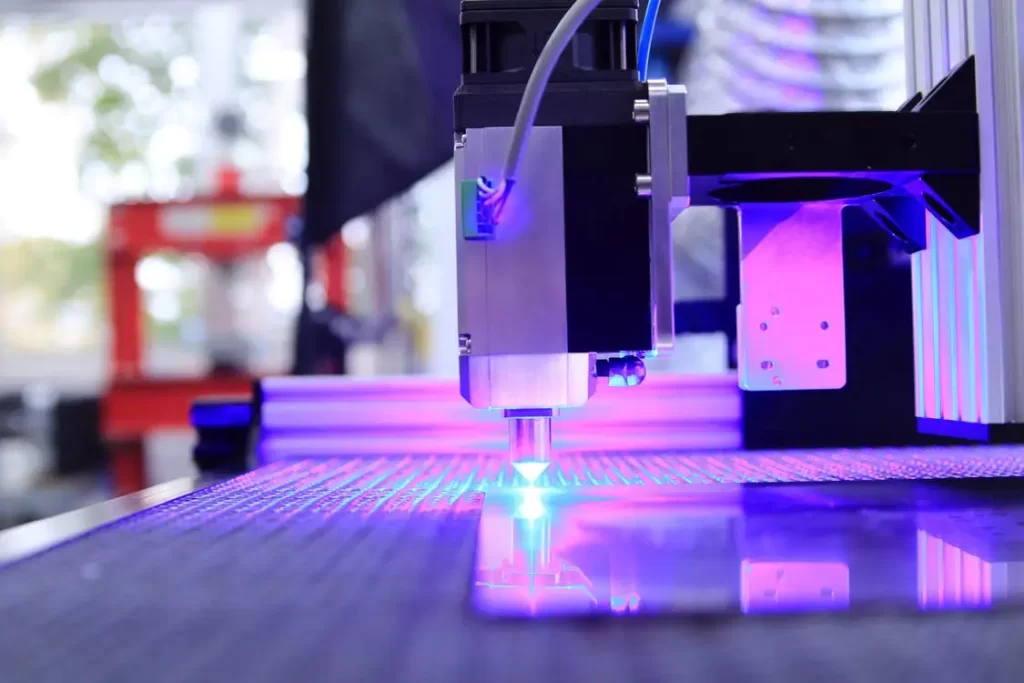

Direct Diode Lasers

Direct diode laser technology is emerging in the field of solid-state lasers. As a result, several laser beams emitted from laser-emitting diodes of different wavelengths are superimposed using beam combining techniques.

Unlike fiber lasers, direct diode lasers do not include a brightness-enhancing stage, giving them lower optical losses and higher wall-plug efficiency. However, for the same reason, direct diode lasers are currently of lower beam quality compared to fiber lasers.

Direct diode lasers at multi-kilowatt levels of power are commercially available and have been successfully used for sheet metal cutting applications.

Cutting Power of Laser Beam Cutting

There are many factors that can affect the cutting power and overall cutting quality of laser beam cuts. Most commonly, these are the type of laser, laser power, properties of laser cutting machine, lens, cutting gas and many more. Since we discussed many of these factors above, we will focus on laser power, lens, and cut metal properties.

Laser Power

Before your laser beam cutting application, you should adjust the power of the laser according to the material thickness. On the contrary, reducing laser power may be necessary to achieve high accuracy on complex geometrical shapes or very small parts.

Most commonly, you will need at least 1000 W to cut carbon steel thicker than 5/16”. Meanwhile, laser pulse frequency can be matched to the relevant machining task, and it can make it easier.

Importance of Lens

Focusing a laser beam will increase cutting capability, and it was usually done by a lens (sometimes with a concave mirror). The lens is defined by its focal length, which is the distance from the lens to the focused spot. The crucial factors that affect the efficiency of the laser process are the focused spot diameter and the depth of focus.

Since these two factors can affect the efficiency of the laser resonator, it is possible to optimize them for each material thickness. However, this would increase set-up time when changing laser cutting projects, which would have to be balanced against the increased speed. In reality, changing the lens is rare. A compromised cutting speed is used unless a specific job has special requirements.

Metal Properties

Each material has its unique mechanical properties which can affect the efficiency of laser cut. Thermal conductivity, absorption, reflectance are just a few of them. Therefore, cutting different types of material thickness and materials will require different laser cutting methods, and we mentioned the most commonly used ones.

Another thing that can cause issues with a laser beam is the reflective properties of materials. For example, highly reflective materials such as pure aluminum, produce a strong reflection of the laser beam, and therefore also, poor cutting and laser marking processes result.

Advantages and Drawbacks of Laser Cutting

Advantages

- Non-contact Technique

- A highly accurate and precise method

- Little to no post-cutting processing of cutting edge

- A cutting procedure suitable for hard-to-cut materials

- No residual stress with small HAZ

- Wide options of types, suitable for different material thickness

- Superior cuts

- Capable of cutting small and complex parts

Disadvantages

- High initial investment

- High expertise required for operation and maintenance

- Other processes such as plasma cutting can cut thicker materials with the same power

Resources:

- https://www.twi-global.com/technical-knowledge/job-knowledge/cutting-processes-laser-cutting-052

- https://www.iqsdirectory.com/articles/laser-cutting-service/laser-cutting.html

- https://laserfab.net/services/#laser-cutting

- https://www.esabna.com/us/en/education/blog/laser-cutting-process

- https://www.trumpf.com/en_US/solutions/applications/laser-cutting/