The plasma arc welding process (“PAW”) is similar to TIG welding because the arc is formed between the tungsten electrode and the welded piece. But this process has some significant differences.

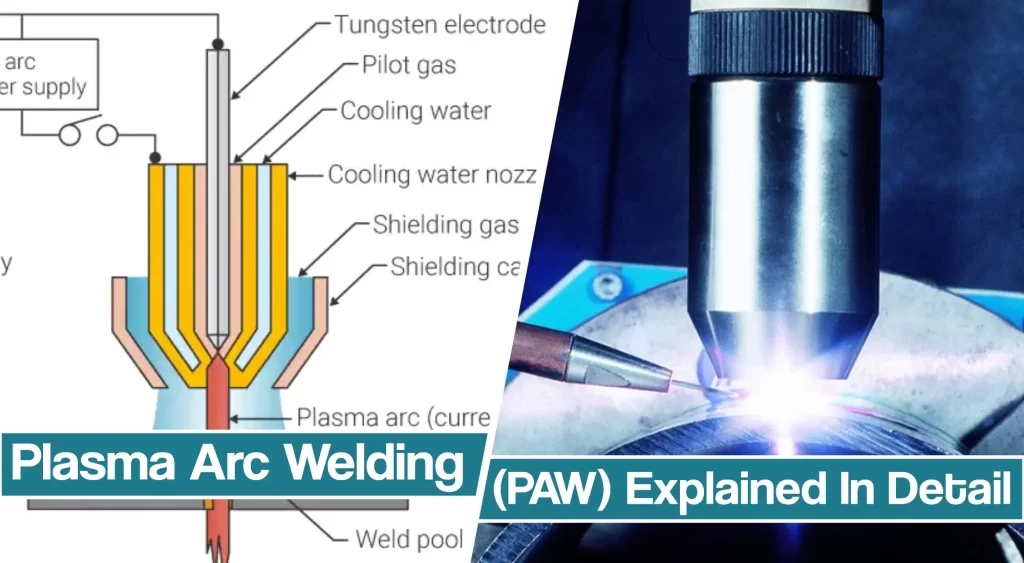

Unlike the TIG welding process, the plasma welding torch keeps the tungsten electrode within the torch’s body without any stick out.

Additionally, there is a fine-bore copper nozzle that constricts the arc and concentrates plasma onto a metal, welding it with a high heat stable arc. In this article, you’ll learn what plasma welding is, how it works, the advantages of plasma welding, and some shortcomings.

What is Plasma Welding?

The plasma welding process joins metals, achieving coalescence by heating with a constricted arc between the workpiece and an electrode, or the constricting nozzle and the electrode.

The plasma process requires an inert shielding gas or a mixture of such gases. Additionally, the process may use filler metal if necessary.

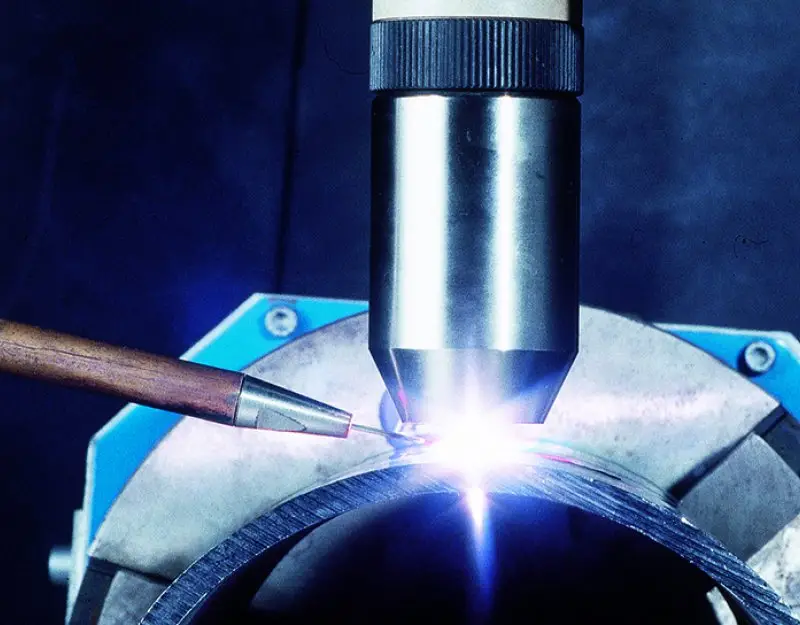

This process allows deep penetration and fast welding times. It’s usually automated, but it can also be manually performed.

Plasma is the fourth state of matter. It’s made up of excited ions, electrons, atoms, and molecules. Lighting is the best example of plasma found in nature. However, in welding, the meaning of plasma has shifted to refer to the state of an electric arc that is constricted by a nozzle.

In plasma welding, the water-cooled small-diameter nozzle constricts and squeezes the arc, increasing its pressure and heat, creating a plasma arc that welds with extreme heat in a small area.

What is the difference between TIG and plasma arc welding?

Plasma arc welding (PAW) and tungsten inert gas (TIG) welding are both arc welding techniques that use an electric arc to melt the workpiece and filler material. Both methods use tungsten electrodes to create the arc, however, there are some differences between these two welding techniques.

The difference is that in plasma welding, the arc is sharply constricted by a cooled gas nozzle through which a flow of plasma gas is directed. The shielding gas flows through the outside gas nozzle, providing an optimum gas shield to the weld seam. Plasma arc welding uses a more focused and intense arc than TIG welding. This allows for higher welding speeds and deeper penetration. As a result, Plasma welding can be used to weld a wider range of materials, including thicker materials, whereas TIG welding is typically used for thinner materials.

Overall, both plasma arc welding and TIG welding are highly versatile and produce high-quality welds. The choice of which technique to use will depend on the specific requirements of the welding application, such as the type and thickness of the material being welded, the desired welding speed, and the available equipment and resources.

Microplasma Welding (0.1 – 15A)

One of the advantages of the plasma welding process is that it can be used with extremely low amperage output. As low as 0.1A. This allows the welding of thin sheets, wire and mesh sections, and similar thin gauge materials. The stiff, needle-like arc minimizes distortion and arc wander.

Medium Current Welding (15 – 200A)

Using plasma welding in a melt mode with high amperage output makes for a great TIG welding alternative. It achieves deeper penetration due to a higher plasma gas flow and a better tolerance to surface contamination, including from coatings. Since the electrode is contained within the torch body, it cannot be contaminated.

Keyhole Plasma Welding (Above 100A)

When performing plasma welding with energy above 100A, distinct keyhole welds are achieved. A powerful plasma beam creates a keyhole shape that progressively cuts through the metal with the molten weld pool flowing behind to form the weld under surface tension forces. The keyhole plasma welding process is used for welding very thick metals in a single pass.

Plasma Arc Welding Equipment

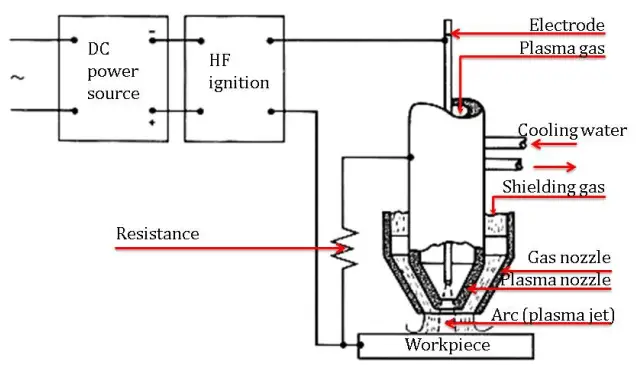

Plasma welding is an arc process and requires a similar setup to most other arc welding processes, including a power supply, shielding gas, and a torch. Below is a more detailed analysis of the necessary equipment:

Power Source

Typically, a DC power source is used for plasma welding that has a drooping characteristic and an open-circuit voltage (“OCV”) higher than 70V. The OCV is necessary to initiate and maintain an arc. But, if you use a helium shielding gas, the OCV must be higher than 70V.

Additionally, it is preferable for the power source to have a high-duty cycle if it’s necessary to achieve high amperage and long welds. Otherwise, the power source will overheat and require cooling down.

PAW Welding Torch

The plasma welding torch is quite similar to the TIG welding torch. It uses a tungsten electrode housed within a collet that’s threaded to the torch body. However, unlike the TIG torch, the PAW torch keeps the entire tungsten electrode inside the nozzle without sticking out.

Additionally, the torch must be actively water-cooled. The arc is contained within the nozzle and causes high heat to accumulate. If the water cooling is interrupted, the nozzle will melt.

The tungsten electrode used for a plasma arc welding process is EWTh-2, otherwise known as a 2% thoriated tungsten electrode. The nozzle is made of copper, but the plasma nozzle bore diameter must not be too small for the current output and plasma gas flow rate because it can melt and erode fast.

Wire Feeder

In automatic welding, the wire feeder can be added to supply a filler metal automatically. A wire feeder needs to have an adjustable wire feeding speed and have a constant output once set.

Control Console

The control console contains a high-frequency arc starting unit, a non-transferred pilot arc power source, a torch protection circuit, water, and gas valves, delay timing systems, and separate flow meters for the plasma gas and the shielding gas.

Advantages Of Plasma Arc Welding

Welding with arc plasma gas offers multiple advantages compared to the conventional TIG process and other arc welding processes. So, let’s take a look at the most prominent benefits:

Focused Arc

The small orifice opening at the tip of the PAW torch outputs a focused arc, and this leads to the following advantages:

- Deeper penetration

- Reduced heat affected zone (“HAZ”) leading to less metal distortion

- Increased travel speed increases productivity

- Lower magnetic field influence on arc stability

- Excellent precision using automated systems

Arc Transfer

The plasma welding process doesn’t necessarily have to use a high frequency to transfer the arc from the electrode to the workpiece. This is an advantage when used in automated and robotic systems because high frequency can interfere with sensitive electronics.

Arc Control

Besides the control available on the power source and control panel, the plasma torch can be used to additionally control the arc and the resulting weld bead. It is possible to modify the tip hole size, gas flow rates, and electrode setback, allowing increased flexibility for a wide range of applications.

Protected Electrode

Since the tungsten electrode is contained within the plasma torch and shielded by a shielding gas, it remains in good condition for a long time. This allows the automation to take place because otherwise, the constant need to condition the electrode would hinder the work productivity.

Shield Gas Selection

The arc plasma process uses an inert gas for the plasma jet shielding. It is possible to use various shielding gases to enhance the welding process. For example, using an Argon-Hydrogen mix of 2-5% can be used as a plasma gas or a shielding gas in combination with pure argon.

Where And Why Is Plasma Used?

Plasma welding meets the high quality and productivity standards of many industries, especially where stainless steel and noble metals are used as base materials.

It is a good process for welding subassemblies like flanges, tubes, elbows, and similar parts that are fitted together. Typically, such elements are used in shipyards and offshore drilling platforms, thermal power plants, refineries, and chemical plants.

It is also applied when manufacturing large cylindrical storage tanks in a flat position or standing on the bracket.

Thanks to its low distortion and high welding speeds, plasma welding eliminates most post-welding straightening operations. It also reduces the amount of necessary filler metal and achieves high-quality results on radiographic tests.

Thanks to these advantages, plasma welding is often applied in the following industries:

- Cryogenics

- Storage tanks

- Fabrication

- Battery manufacturing

- Automotive

- Medical

- Aerospace

- Pipe welding

- Power plants

- Thermocouple industry

- Stainless steel industry

- Tool and die repair

- And many others

Conclusion

Plasma welding works great when used in suitable applications. Thanks to different modes, it covers a wide range of uses from micro plasma to keyhole mode that allows hot ionized gas to weld thicker material.

This process is not new, but it has gained popularity in the last few decades thanks to its arc characteristics and multiple advantages over conventional arc welding processes.

Sources:

- What is Plasma Welding? at Abricor Binzel

- Plasma Arc Welding at TWI Global

- What is plasma welding? – The Fabricator