Welding aluminum is a lot different compared to working on other types of materials. I know people who even with years of experience are still having trouble doing it.

Aluminum welding is literally a skill on its own and is a hundred light-years away from welding steel or mild steel.

Luckily, it is not something impossible to learn. As with every form of welding, this one too takes practice, patience, and determination. You have to employ different techniques that are unique to the welding process used for working on aluminum.

It can be a bit difficult to master, but if you strive for perfection it can be done quite easily. Today, we tackle the topic of welding aluminum in detail.

Aluminum Properties

Aluminum is one of the most commonly used materials for fabrication. It has many positive characteristics like being non-corrosive, lightweight, and is visually appealing. Unfortunately, all the positive sides of aluminum are what make it difficult for fabrication.

In some cases, depending on the material at hand, welding principles are generalized and cover a wider range of metals. The case with aluminum is far from it. Aluminum behaves differently compared to other metals, which makes it difficult to determine the weld progress and quality.

| Properties | Density g/cm³ | Resistance ( Ωmm²/m) x10² | Thermal Conductivity cal/cm²/cm°Cs | Thermal Coefficient (mm/mmºC) x 10-6 | Melting Temperature °C | Tensile Strength N/mm² | Elongation % | Hardness HV |

|---|---|---|---|---|---|---|---|---|

| Aluminum | 2.70 | 2.66 | 0.52 | 24.00 | 660.00 | 91.50 | 30.10 | 57.98 |

Metal Characteristic

One of the more unique characteristics of aluminum is that it gives off no spark in a spark test. A visual fracture will show a smooth and bright structure. Also, it does not become red just before starting to melt. You will also notice a white, heavy film of oxide starting to form almost instantaneously as pure aluminum melts.

Aluminum is also very light and will continue to have favorable ductility even at sub-zero temperatures. It is also resistant to corrosion, has good thermal and electrical conductivity, and high reflectivity to light and heat.

Color Of Aluminum

You will easily recognize aluminum based on its color. It basically resembles silver as it is light gray to silver in tone. It shines brightly when polished and dull when oxidized.

Aluminum Thermal Conductivity

As mentioned, aluminum has high thermal conductivity properties and is able to conduct heat three to five times as fast as steel. However, the melting temperature is less than steel, so having to put more heat into it is where the difficulties of welding aluminum lie.

The best solution is to preheat the metal prior to welding, particularly when working on thicker sections. However, high conductivity can be sometimes helpful because the weld will solidify faster, particularly if the heat is pulled away from the weld really fast.

This trait, combined with surface tension, helps the weld hold together and allows easier all position gas tungsten arc welding and gas metal arc welding more practical. Something that you also need to note is that aluminum welds decrease 6% in volume after they solidify.

Aluminum Vs Steel Welding and Properties

| Properties | Strength to Weight Ratio | Corrosion Resistance | Thermal Conductivity | Cost | Workability | Welding | Thermal Properties | Electrical Conductivity |

|---|---|---|---|---|---|---|---|---|

| Aluminum | Lighter but better ratio | Higher Oxidation and Corrosion resistance | Much better thermal conductivity | More Expensive per pound | Soft and easy to cut and form | Harder to weld | Lower melting temperature | Great conductor |

| Steel | Heavier but worse ratio | Prone to Oxidation and Corrosion | Lower thermal conductivity | Cheaper | Harder, can be hard to work with | Easier to weld | Higher melting temperature | Poor conductor |

Difficulties With Aluminum Welding

To put it simply, welding aluminum is difficult because of it being soft, having a lower melting point, and having a tougher oxide layer. In its molten state, aluminum is susceptible to impurities, which can result in porous and weak welds.

As mentioned, aluminum has a great affinity for oxygen. Its melting point is at 1,200°F (650°C), but the oxide that protects the metal melts at 3,700°F (2037°C). This means that the oxide must be cleaned from the metal before starting to weld.

Due to the fact that aluminum possesses higher thermal conductivity but a lower melting point, it allows a much smaller window of workability which could easily result in burn though if not handled correctly. The most common factors that make welding aluminum difficult include:

- Thickness – A welder has to be careful to avoid burn through and at the same time apply enough heat to work on thicker sections of metal.

- Porousness – In a molten state, aluminum will absorb hydrogen quicker as it heats up. As the metal solidifies, bubbles may remain and make it porous.

- Oxidation – Aluminum oxide is found on top of the material, which melts at a higher rate than pure aluminum. More heat is needed to melt the aluminum oxide layer but the welder needs to be careful not to burn through the material once they get through.

- Impurities – Aluminum is very sensitive and can easily be contaminated by air, dirt, and even water during the welding process. Thorough cleaning is needed before starting to weld it.

Aluminum Alloys and Their Numbers

In order to enhance the physical and mechanical properties of aluminum, its pure form is often alloyed with many other metals. The elements within aluminum alloys are used as a basis to classify them into non-heat-treatable and heat-treatable alloys.

The numbers under which they are recognized go like this:

| Alloy | Alloyed Material |

| 1XXX series | 99% or higher aluminum alloy, used mostly in the electrical and chemical industry. |

| 2XXX series | Copper is the primary alloy here and offers high strength. However, these do not possess good corrosion resistance. These are often used in the aircraft industry. |

| 3XXX series | Manganese, of about 1.5%, is used here but is non-heat-treatable. These aluminum alloys are very workable and have moderate strength. |

| 4XXX series | Silicon is added here and lowers the melting temperature. This alloy is often used for brazing and welding electrodes. Most of the alloys belonging to this group are non-heat-treatable. |

| 5XXX series | Magnesium is the alloying element here which allows for medium strength. It offers very good welding characteristics and corrosion resistance, but should not be used in cold work. |

Aluminum Weld Preparation

The biggest challenge of welding aluminum is being able to avoid impurities. As mentioned, contaminating the weld may lead to a porous or non-quality joint, which you definitely do not want. This is why proper preparation is very important as it prevents aluminum from contaminated.

Keeping It Clean

Before starting to weld aluminum, you need to make sure that everything is clean. This also means removing lubricants from the metal. After degreasing, you need to remove the aluminum oxide layer which should be performed with a wire brush. A hand brush or a cup wire brush work equally well.

If you decide to use a power wire brush, you need to keep the rmps and the pressure down so as to avoid smearing. In order not to contaminate the base metal, be sure to use only the brush meant for aluminum cleaning.

- Chemical cleaning – This involves using fluxes. Fluxes are usually used for brazing, gas welding, and soldering. Aluminum electrodes are covered with a coating that maintains fluxes for cleaning the base metal.

- Electrical oxide removal system – This one uses cathodic bombardment which occurs during the half-cycle of alternating current gas tungsten arc welding when the electrode is positive.

| Removed Compounds | Way to Clean It |

| Oil, Grease, Moisture & Dust | Solvent or alkaline cleaning solution, Oxide removal spray (or vinegar), Microfiber rags, Hot water |

| Aluminum Oxides | Alkaline solution Proprietary deoxidizers Stainless steel wire brush Grind, fill Scrape all joints and surfaces before welding |

Edge Preparation and Polarity Settings

The joint design of steel joints is very similar to aluminum joints. However, welders should be wary of some general principles due to the higher fluidity of aluminum under the welding arc. The best way to approach it is joint preparation.

A specially designed V groove is best to use especially when welding is done from one side only where the welder aims for a smooth, penetrating weld bead. The bottom of the V groove has to be wide enough to contain the root pass completely. One should add a lot of filler alloy to fill the groove.

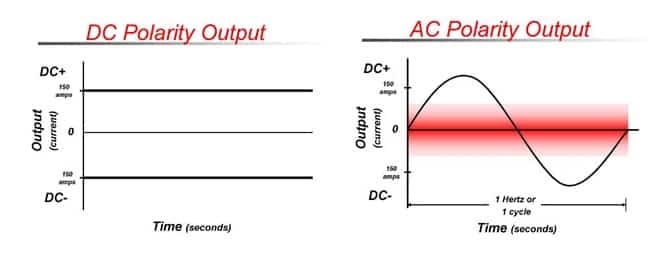

This type of edge preparation is used for welding in all positions. It can eliminate the possibility of burn-through or over-penetration in a horizontal welding position. The current and polarity settings actually vary based on the type of electrodes used. Polarity can be determined with a trial method on the joints you wish to work on.

Common Aluminum Welding Processes

In order to weld aluminum, you can’t just pick up any old welder and start going at it. You need to know which welding process to use. The most commonly used ones are Gas Tungsten Arc Welding (GTAW)/TIG welding and Gas Metal Arc Welding (GMAW)/MIG welding.

On top of that, you will need a quality machine to do it. Regardless of the process, you choose you should get the best welder for aluminum if you wish to have a welding experience that is not limited by the equipment.

Gas Tungsten Arc (TIG) Aluminum Welding (GTAW)

Gas Tungsten Arc (GTAW), which is also referred to as the tungsten inert gas (TIG) welding process, is one of the favorite processes of skilled welders for welding aluminum.

It is primarily used in the automotive industry and more often than not by racing teams.

This process consists of a constant current (CC) with alternating current (AC) capabilities and a shielding gas of 100% Argon.

![Welding Aluminum Explained in Detail - [Popular Welding Processes, Weld Preparation, Welding Tips and Techniques 2023] 3 image of TIG welding](https://weldingpros.net/wp-content/uploads/2021/06/TIG-Welding-Aluminum-compressed-e1623317767971.jpg)

It does not require a wire feeding system to be used as it may create feed ability issues. Instead, the welder feeds the filler material into the weld puddle directly.

The biggest advantage that this method as opposed to other welding processes is that alternating current cleans the oxide layer of the aluminum as you work. This keeps the weld metal clean from any contamination.

Alternating Current GTAW Aluminum Welding

A GTAW welding process that uses alternating current produces an action that cleans the oxide layer from the base material.

A hundred percent Argon shielding gas is used and if you really want to get the best results, you better use equipment that is capable of producing a balanced wave or equal current in both directions.

Direct Current Straight Polarity Aluminum Welding

This welding method more profane when you are working on thicker material. The combination of helium and thoriated tungsten electrodes holds many applications and advantages for most of the automatic welding processes.

Since you don’t have to heat the welding wire so much, a smaller aluminum electrode can be used for a certain current. This helps in keeping the welding bead narrow. Also, using direct current straight polarity offers a better heat input compared to an alternating current.

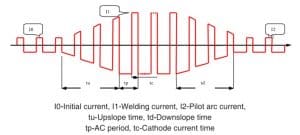

Square Wave Alternating Current GTAW Aluminum Welding

A square wave alternating current shapes the current wave in a square, cyclical wave pattern and not in a standard smooth sine wave cycle. Using square wave means that the power supply is using the Balanced Wave Control feature to create the arc, creating better penetration and a clean surface.

Penetration happens during the negative part of the wave cycle, while cleaning occurs during the positive side of the wave cycle and a change in portions of the cycle will enable you to get the necessary characteristics.

This process is done by using Silicon Controlled Rectifiers as control gates for the currents. However, precise timing must be achieved as these gates open and close. But if you get it right, the result is a crips arc.

Tips and Techniques For TIG Aluminum

When TIG welding aluminum, there are a few tips that will help you get better results.

- Use the correct Tungsten electrode rod. Pure tungsten electrodes work best when you weld aluminum.

- Too much Argon flow through your welding torch can cause an irregular arc.

- Be sure that your base material is prepared, cleaned, and preheated.

- A heat sink can help to avoid warping.

- Keep the filler material clean. A filler rod that is free of contaminants should be melted with the base metal to create a proper weld pool.

Gas Metal Arc (MIG) Aluminum Welding (GMAW)

Gas Metal Arc Welding (GMAW), usually called metal inert gas (MIG) welding, is another welding process commonly used for welding aluminum. Compared to TIG, MIG welding aluminum has a faster travel speed and higher deposition rates.

It typically results in improved weld quality.

But it does require a mechanical wire feeding system to be used which also means using a spool gun or a push-pull gun for the aluminum wire feeding to work.

![Welding Aluminum Explained in Detail - [Popular Welding Processes, Weld Preparation, Welding Tips and Techniques 2023] 6 image of mig welding](https://weldingpros.net/wp-content/uploads/2021/06/Mig-welding-compressed-e1623319111717.jpg)

Proper shielding gases need to be used, pure Argon is desirable, so as to keep the aluminum filler metal and the base metal clean. It will protect the weld area and eventually prevent porosity.

Shielding Gas and MIG Welder Settings

![Welding Aluminum Explained in Detail - [Popular Welding Processes, Weld Preparation, Welding Tips and Techniques 2023] 7 Argon bottle](https://weldingpros.net/wp-content/uploads/2021/04/Argon-bottle-e1618915693650-300x253.jpg)

Since aluminum is a non-ferrous metal, a 100% Argon shielding gas is needed with a recommended flow rate of 20 to 30 cubic feet per hour. When you MIG weld aluminum, it is best to use the spray transfer mode.

This is because this mode allows a very smooth transfer of molten aluminum droplets from the end of the welding electrodes to the weld pool.

The droplets are also smaller in diameter and there is also no short-circuiting when this process is used. It is very effective and has a high deposition rate.

Unfortunately, spray transfer also comes with high heat. Too much heat means a large weld pool with penetration that could be hard to control. It is best used for thick material of about 14 gauge. A spool gun should improve the feeding of soft aluminum wire and also eliminate the possibility of birdnesting.

Choosing Filler Metal

Choosing the correct filler metal when welding aluminum is paramount. It works best when you know the alloy of the base metal and the conditions the finished piece is going to be subjected to. The most commonly used filler metal wires to weld aluminum are ER4043 and ER5356.

MIG Aluminum Welding Tips and Techniques

Once again, here are a few tips that might help you out from a sticky situation when you MIG weld aluminum.

- A 10 to 15-degree push travel angle should be used. A pulling or dragging angle creates less gas coverage and may create a dirty weld and porosity.

- When MIG welding, reflective heat and weld puddle can get really hot. If you hold the tip too close, the wire may burn back and cause feeding problems.

- Proper tip-to-nose distance should be maintained. The contact tip should be recessed around 1/8 inch inside the nozzle.

- Large weave beads should be avoided when welding aluminum. Multiple pass straight beads create a better appearance, less cold lapping, and burn through.

- Faster travel speeds of the welding torch are needed as the base metal heats up.

Other Ways to Weld Aluminum

MIG and TIG may be the most popular welding processes used for welding aluminum, but there are several other ways that one can successfully do it.

Shielded Metal Arc (Stick) Welding

Shielded Metal Arc Welding, commonly referred to as the Manual Metal Arc Welding process (MMA), is a method that was utilized way before GTAW and GMAW. When welding aluminum, this process uses a flux-coated welding electrode, which is basically straight-length aluminum rods covered in flux.

Unfouratnely, this welding process comes with its downfalls as flux entrapment can lead to corrosion. This is most apparent in fillet welds where the flux trapped behind the weld starts to create corrosion from behind. The process may also cause the porosity of the created weld.

![Welding Aluminum Explained in Detail - [Popular Welding Processes, Weld Preparation, Welding Tips and Techniques 2023] 8 Image of stick welding worker](https://weldingpros.net/wp-content/uploads/2021/06/stick-welding-compressed-e1623322037820.jpg)

Stick Welding Rods

Stick welding rods come at material thicknesses of about 1/8″ of steel. They serve well when doing repairs on tanks or pipes in the field. They are not really useful for any precise work but work pretty well in windy conditions. The disadvantage lies in having to practice a lot if you want to use them. There is also the issue with flux as it burns aggressively and is hard to remove. It can also burn through paint.

Aluminum Plate Welding

Aluminum plate welding can be useful but also has several downsides. It is quite difficult to control the arc while butt and fillet welds are hard to make in plates that are less than 1/8 in. (3.2 mm) thick.

When working on plates that are heavier than 1/8 in. (3.2 mm), a joint created with a 20-degree bevel will equal to a weld made through the oxyacetylene process.

Gas Welding

The oxyfuel gas welding process achieves coalescence with the heat created from an oxygen-fuel gas flame and an active flux to remove the oxide and shield the weld pool when aluminum welding. The most common use is for sheet metal but is also useful in working on greater metal thicknesses.

Unfourantely, this type of welding is only good for working in the flat and vertical position. Distortions can be quite extreme as well. This process is also known to cause corrosive flux and high heat input.

Laser and Electron Beam Welding

Beam welding techniques come as highly recommended when welding aluminum. The most common ones are electron beam welding and laser beam welding.

Electron beam welding creates an easily controlled and precise heat-affected zone. On the other hand, laser beam welding works fast and creates clean welds which are needed for metals that are sensitive to cracking.

Resistance Welding

This process requires a welding machine that is able to apply pressure and pass current through the areas that are joined together. It is also possible to use it to weld aluminum, but the welder needs to be aware of the high thermal and electrical conductivity properties of aluminum.

Spot welds are designed to carry shear loads. However, if combined loads or tension are added to the mix, special tests need to be done. The strength of spot welds in direct tension usually varies between 20 to 90% of shear strength.

Shielded Carbon Arc (CAW) Welding

The shielded carbon arc welding process is another one that can be used to weld aluminum. It does require flux but creates welds that look like and have a similar structure to either oxyacetylene or oxy-hydrogen welding. This process can be done both manually and automatically.

Manual shielded carbon arc welding is limited to the material thickness of up to 3/8 in. (9.5 mm). Joint preparation is almost the same as with gas welding and flux-covered rods are used.

Electroslag Welding

Electroslag welding is only good for welding pure aluminum but not so good for aluminum alloys. Submerged arc welding can be used as an alternative if an inert gas is not available.

Aluminum Stud Welding

![Welding Aluminum Explained in Detail - [Popular Welding Processes, Weld Preparation, Welding Tips and Techniques 2023] 9 image of stud welder](https://weldingpros.net/wp-content/uploads/2021/06/stud-welding-compressed-e1623322201217.jpg)

Aluminum stud welding is performed with conventional stud welding equipment. You can use either a capacitor discharge or a drawn arc capacitor discharge technique.

The conventional process may be used to weld studs of 3/16 to 3/4 in. (4.7 to 19.0 mm) diameter.

The stud welding gun is modified so it has an adapter that maintains the high purity of the shielding gas.

Reverse polarity is used for this process, with the electrode gun being positive and the workpiece being negative. A small cylindrical cone found on the end of the aluminum stud is meant to start the arc and establish the arc length needed for aluminum welding.

Common Mistakes in Aluminum Welding

After learning how joining aluminum works, it is also helpful to know the possible mistakes one can make when working on aluminum.

- Aluminum requires a different approach compared to when you weld steel or other materials. There isn’t a one-size-fits-all method here, unfortunately.

- Proper protection is still needed. You need to wear your safety glasses, welding helmet and educate yourself on all the potential dangers that come with welding aluminum.

- Preparation is key, especially when it comes to welding aluminum. Properly clean and store the material you are about to be working on.

- Don’t forget about the small details. When it comes to welding aluminum and welding in general, a small step can lead to crater cracking, porosity, and all sorts of things that you do not want.

- It takes time to weld aluminum. Be patient stick to all of the good practices mentioned in this article.

Good Sides of Aluminum

Aluminum is fairly young when it comes to it being used as a structural material. The Washington Monument, completed in 1884, was capped off with a 100 oz. aluminum pyramid because it was considered a precious metal back then.

It was only in 1886 that aluminum started to be used for commercial use with the discovery of the electrolytic process which includes obtaining pure aluminum from aluminum oxide.

To weld aluminum takes time, and even though it has several key benefits it is still quite difficult to master.

- Lightweight – compared to welding steel, aluminum has a better strength to weight ratio. It becomes stronger and not brittle with decreasing temperatures.

- Electricity and heat conductivity – Aluminum has similar properties when conducting heat and electricity as copper.

- Non-corrosive – Oxidation may be troublesome to avoid while welding, which is why the non-corrosive properties of aluminum are beneficial.

- Recyclable – The increased popularity of aluminum is owed to its cost-effectiveness and recyclability.

- Appearance – Aluminum easily absorbs paint and sealant.

Conclusion

There you have it, everything you need to know about how to weld aluminum. It is a bit hard, but quite rewarding once you master it. If you are willing to invest a bit more time to really get good at it, the rewards are going to be quite high.

Resources:

- Nature of the stable oxide layer formed on an aluminum surface by work function measurements by Vijay K.Agarwala, TomlinsonFortJr.,

Department of Chemical Engineering, Case Western Reserve University, Cleveland, Ohio 44106, U.S.A. - A short history of welding aluminum by ESAB

- Introduction to Welding Aluminum by Oanh Nguyen at TWS.edu

- Guide for Aluminum Welding at academia.edu

- Welding of Aluminum Alloys to Steels: An Overview at researchgate.net