Cold metal transfer welding is a modified MIG welding process that drastically reduces the heat input while increasing the deposition rate.

CMT welding outperforms traditional MIG and TIG welding processes, making it one of the most advanced welding methods to date.

While the term “cold” implies the absence of heat, this process actually relies on controlled, drastically reduced heat input.

![Cold metal transfer welding [CMT] - How it works 1 Featured image for the cold metal transfer welding article](https://weldingpros.net/wp-content/uploads/2022/06/CMT-cold-metal-welding-1024x563.webp)

Compared to traditional MIG, the CMT inputs only 10% heat into metal. That’s why the process is called cold metal transfer welding.

In this article, you’ll learn how cold metal transfer welding works, why it’s preferable to traditional MIG welding, its applications, and the prominent advantages and disadvantages.

How Does Cold Metal Transfer Welding Work?

Essentially, CMT works by precise pulsing between the base and high current phases. This process differs from MIG/MAG welding.

Because the deposited metal and the applied current are digitally controlled, allowing never-before achieved thermal control.

The CMT welding uses very similar equipment to the MIG welding process. The ground clamp, MIG torch, wire feeder, and shielding gas are not much different. The most significant difference is in the welding machine.

While the standard metal inert gas welding process operates on the continuous short circuit principle, the CMT process uses low and high currents at specific moments to avoid short circuits at high currents. On the filler metal side, it digitally controls the wire movement back and forth to aid the deposition.

There are two crucial phases of the CMT process:

- When the electrode wire tip comes into contact with the molten pool, the CMT welding machine senses it, and the torch retracts the wire via digital process control. As the wire is retracted, the droplet starts to form. At that point, the current is lowered to near zero, the droplet falls into the weld pool, and the metal transfer is completed.

- Next, the arc is reignited with high amperage in a very brief period, and the wire is fed forward until it touches the weld pool again.

In a nutshell, the CMT welding process alternates between the two described phases many times per second. The heat input only happens in the very brief phase as the wire is pushed into the weld pool.

There is no need for the wire to continuously receive energy as it retracts because it’s already ready to melt off into the weld pool. So, since the wire is no longer energized as it retracts, the spatter is brought to a minimum, and the heat input is drastically reduced.

Essentially, the CMT welding process is a much more efficient version of the MIG welding process. The inventor of the CMT welding process is the Austrian manufacturer Fronius International GMbH, and they describe the cold metal transfer as a sequence of “hot-cold-hot-cold” current.

Shielding Gas Selection

The cold metal transfer welding parameters depend a lot on the welded material. The same applies to the shielding gas choice. In a nutshell, the CMT is still based on the MIG welding process, so shielding gasses are similar.

CMT requires a mixture of argon and carbon dioxide, pure carbon dioxide, or tri-mixes for stainless steel.

There are also numerous welding gas mixtures with additions of oxygen, helium, hydrogen, and others in specialized use cases.

Different Types of Cold Metal Transfer Welding

There are four different cold metal transfer welding process types. So, let’s describe each in brief.

Cold Metal Transfer Pulse

Cold metal transfer pulse uses direct current electrode positive (DCEP) polarity — ground clamp negative, electrode positive.

This polarity concentrates 70% of the heat on the welding wire (electrode), while the workpiece is subjected to 30% heat only.

This is favorable when welding thin sheet metal products because it avoids excessive heat input.

Cold Metal Transfer Advanced

The advanced cold metal transfer welding process uses alternating current. So, electrode polarity switches many times in a second between positive and negative (DCEP and DCEN).

The polarity reversal takes in the short-circuit phase (the brief moment when the welding wire touches the base metal). The DCEN improves deposition rate, while the DCEP is responsible for targeted droplet transfer.

Cold Metal Transfer Pulse Advanced

The CMT advanced pulse welding process combines the standard CMT cycles with a negative electrode polarity and a pulse phase with positive polarity.

As a result, the process achieves a better filler metal deposition rate during the negative phase with lower heat input. The pulse phase gives the operator the advantage of non-short-circuit droplet metal transfer.

Cold Metal Transfer Dynamic

The CMT dynamic is characterized by a high-frequency wire back and forward action (up to 130 times per second).

This results in a higher deposition rate and deeper penetration. CMT dynamic is best suited for welding thick plates, but it’s not designed for cladding applications.

Where Is Cold Metal Transfer Welding Used?

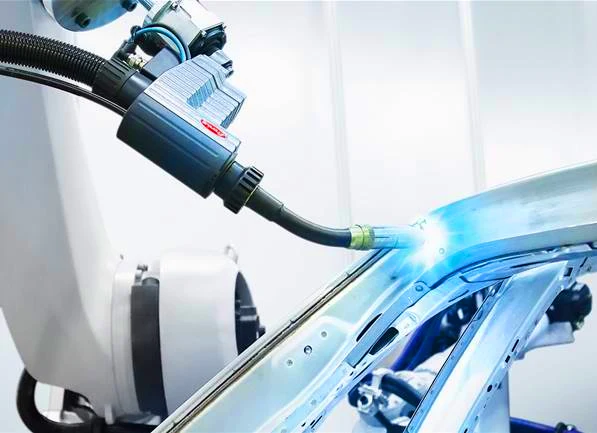

The cold metal transfer welding process has multiple advantages over the conventional MIG welding process. Therefore, it finds use in many industries, but it’s mainly used as an automated cold metal transfer welding method.

Automobile Industry

The automobile industry has adopted the CMT welding processes. Many vehicle brands use CMT to their advantage to produce better welds faster. This is especially true when aluminum is a primary material for a vehicle’s chassis.

For example, the Tesla Model S car frame is made from aluminum to reduce the vehicle’s weight and improve battery autonomy. The cold metal transfer welding is used to create the main panels of the Model S body as a MIG welding alternative.

This is particularly important because automakers and their suppliers continue to work to reduce vehicle weight (and thereby fuel consumption and CO 2 emissions), and in the European Union to meet the 2012 emissions limit of 130 g/km CO 2. In other industrial segments, too – consumer products, construction, energy – lightweight construction delivers noteworthy benefits.

Cladding Applications

Some sensitive metals require advanced methods of surface repair using a cladding process. For example, INCONEL 718 superalloy, aluminum 6061 alloy, AZ31 magnesium alloy, Al-Si-Mn alloy, and similar metals that are challenging for cladding, have shown favorable results when cladded using CMT welding.

Each of these alloys requires a specific approach to CMT welding. A pulse frequency and amperage must be appropriately set for the material thickness and the expected outcome. For example, cladding AZ31 magnesium alloy requires a welding speed of about 1/2 in. per second.

Since the CMT shows favorable results when metal cladding, it can be used to repair worn-out gas turbines, steam turbines, engine parts, and similar elements.

Joining Galvanized Steel

It’s possible to join galvanized steel using a cold metal transfer welding process without damaging the zinc coating on the steel. As a result, the steel keeps its protective zinc layer, and no hazardous welding fumes are produced.

The CMT welding methods don’t create a sufficient heat input to break the zinc layer. However, joining galvanized steel is only possible by brazing with the CuSi3 filler metal.

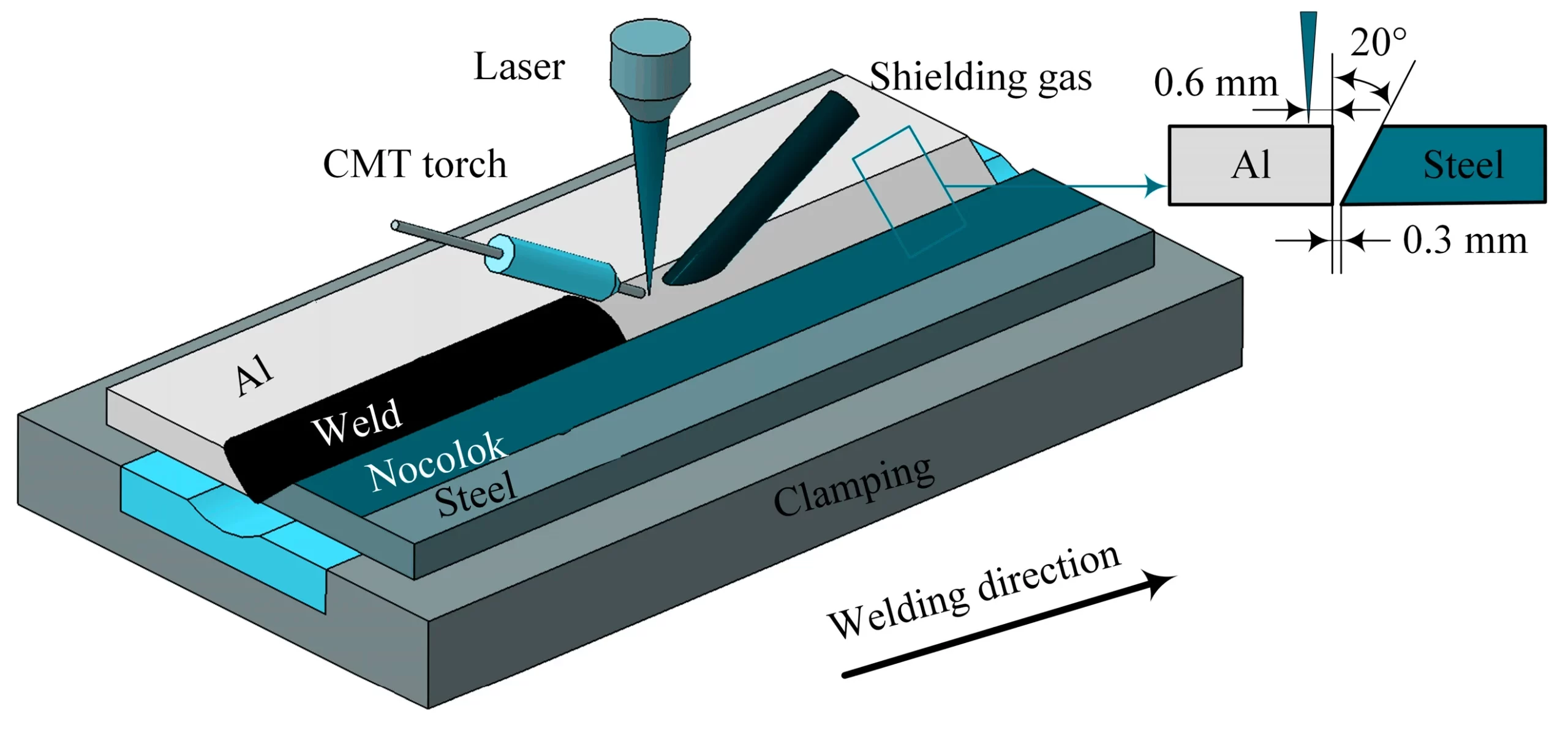

Joining Dissimilar Metals

The most critical applications of CMT welding processes are found in industries requiring the welding of dissimilar metals.

Steel and aluminum cannot be joined by thermal processing, or so it is assumed. Fronius International’s practical success at this objective is a revolutionary solution that has satisfied the expectations of material experts, design engineers, and production engineers. It is a welcome development in the automotive industry, where designers and fabricators will appreciate the dependable, high-load thermal joints between steel and lightweight aluminum.

Using CMT welding, it’s possible to efficiently create a strong joint between aluminum and steel. This is the primary reason to employ the CMT welding process. But, it’s also possible to join aluminum and magnesium alloys, zinc and aluminum alloys, aluminum and titanium, magnesium and copper, and others.

The “textbook” understanding of welding technology maintains that metals with such vastly different physical properties — such as their fusing temperatures (1,500°C versus 590°C), coefficients of expansion (1.2 mm versus 2.3 mm/100°C), or electrochemical potential — cannot be joined by arc welding. Fronius began working on this problem more than two decades ago, and first achieve reproducible joints with its CMT technology.

Advantages of Cold Metal Transfer Welding

- Arc remains stable, even if using a 100% CO2 shielding gas. Achieving a stable arc is almost impossible with a MIG welding process, especially with pure CO2 gas.

- Favorable arc characteristics — the arc path is short and almost perpendicular to the piece. Additionally, arc on time is minimal.

- Ten times lower heat input into the weld joint compared to standard MIG/MAG welding.

- Excellent control over the deposited weld metal.

- The high deposition rate and deep weld penetration.

- Outstanding mechanical properties of achieved welds.

- It can weld thin or thicker materials.

- Welds almost all metals.

- Achieves welds almost on par with TIG welding when it comes to esthetics.

- The cold metal transfer process is one of the best ways to weld dissimilar metals.

- Allows exceptional weld shape accuracy.

- Extremely low dilution during cladding applications.

- Achieves crash-test approved steel and aluminum joints.

- High welding speed.

- Excellent gap bridging abilities.

- Extremely low spatter.

Disadvantages of Cold Metal Transfer Welding

- Relatively expensive.

- Not yet been adopted on a large scale, so part availability may be an issue in some countries. Additionally, there aren’t many trained operators who understand the CMT process and how to monitor and set up the machines.

- Primarily available for robotic cold metal transfer applications. But, there are also cold metal transfer manual welding machines.

Conclusion

The cold metal transfer welding process outperforms traditional MIG welding in every way, except the equipment cost. But, for large-scale manufacturing, the cold metal transfer process is a much better choice long term.

The wire retraction during the CMT pulse when a short circuit occurs and the low thermal input thanks to pulsed welding current, are responsible for exceptional weld parameters achieved with a CMT process.

Resources:

- Cold metal transfer (CMT) technology – An overview by S.Selvi A.Vishvaksenan E.Rajasekar

- CMT – Cold metal transfer at Fronius

- Cold metal transfer (CMT) welding of thin sheet metal products