General Motors Corp. has developed a unique approach to spot welding technology for the automotive industry, but it is also applicable in many other manufacturing processes.

Their approach is tied to the patented multi-ring domed electrode shape, allowing the spot welder to efficiently melt the base aluminum metal underneath the surface oxides.

With this development of welding technology, they can significantly reduce vehicle weight and improve fuel economy and performance.

In this article, we will discuss spot welding, how their welding process works, and the main benefits.

What Is Spot Welding?

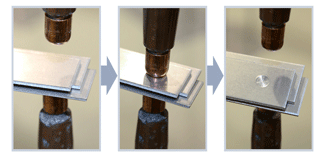

Spot welding is a form of a resistance welding process that uses the resistance of electrical current flow to melt the metal.

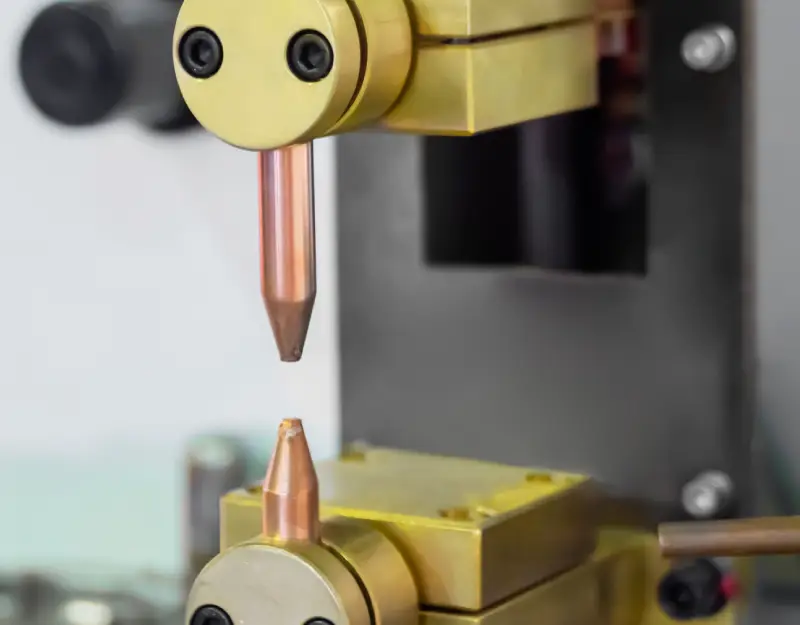

This process uses two copper alloy electrodes to apply pressure in a single spot and conduct electricity. As a result, two or more sheets of metal form solid welds in these spots.

The material melts, and the two opposing electrode pincers pressure fuses the metals together. The electrode pressure is maintained until the “nugget” weld is formed and solidified.

The copper electrodes are used because it has high thermal conductivity and low electrical resistance. This prevents heat build up in the electrodes and makes sure that most of the heat is applied to the metal being welded. There are many different spot welding electrode alloys for different metals, but the conventional resistance spot welding process can’t weld aluminum body structures.

Why Can’t the Standard Spot Welding Method Weld Aluminum?

In theory, you can weld aluminum with a spot welder. However, the copper electrodes quickly degrade because the copper readily forms an alloy with aluminum and the contact heat is high.

The oxide layer of aluminum has a very high electrical resistance. This increases the surface heat and reduces the weld quality.

The oxide layer creates problems with spot welding electrodes because it contaminates them and causes them to stick to sheet metal after a number of welds.

The General Motors Method to Join Aluminum Body Parts

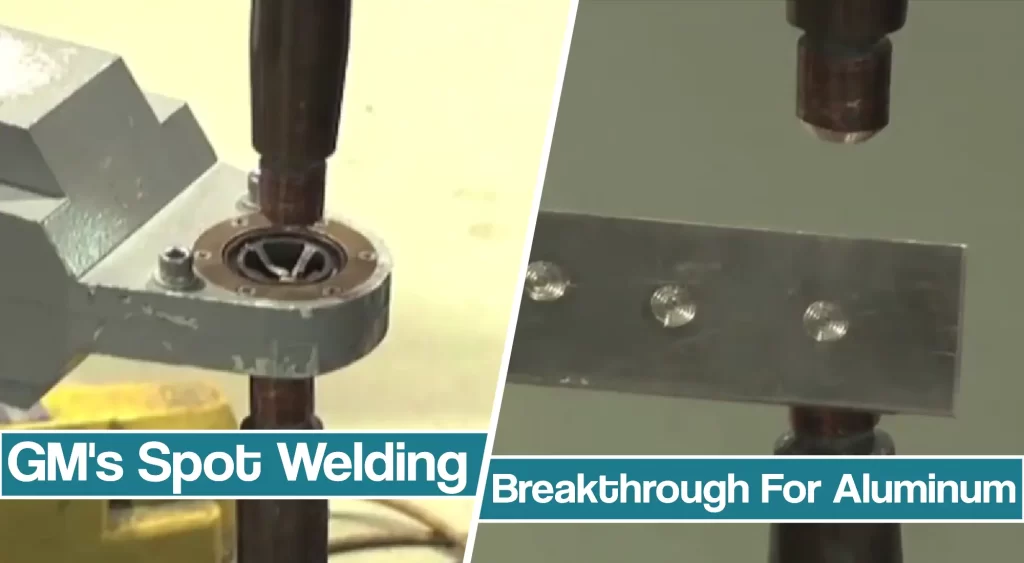

General Motors has patented a spot welding aluminum process that can efficiently weld aluminum to aluminum body structures in an inexpensive manner.

The GM welding breakthrough enables the industry-first aluminum welding technology for spot welding without the traditional issues this process faces with aluminum.

The GM Research and Development created a multi-ring domed electrode that disrupts the oxide layer on the aluminum’s surface, allowing the electrical current to make a strong weld.

This new take on spot welding aluminum works with cast aluminum, sheet, and extruded parts because they all have the same oxide problem.

The Advantages of Spot Welding Aluminum

In traditional automotive manufacturing, the aluminum body structures are riveted using self-piercing rivets to join aluminum body parts. But the rivets from the aluminum body increase the vehicle weight and add cost to manufacturing.

With spot welding aluminum, it’s possible to eliminate nearly two pounds of rivets. Additionally, the rivet guns have a limited range of joint configurations and are costly themselves.

The ability to efficiently spot weld aluminum will help improve fuel economy and performance because lightweight aluminum can significantly reduce vehicle weight. Certain car body parts like hoods, liftgates, and doors can be manufactured from aluminum and reduce their weight by up to 50%. This leads to less fuel consumption and fewer carbon emissions. Both of which are heavily pushed by auto manufacturers and regulatory standards.

But there is also one less obvious environmental benefit this innovative spot welding approach provides. If the self-piercing rivets are not present in the aluminum body structures, this lightweight metal can have a much easier end-of-life recycling. This reduces the recycling costs and the need for new aluminum excavations, leading us closer to the circular economy.

Aluminum is not only going to improve fuel efficiency, but because aluminum parts are corrosion resistant, it will prevent unnecessary wear and improve the vehicle lifespan. So, GM’s patented process that’s used on future vehicles will allow substituting lightweight aluminum for heavier and less durable steel, reducing the overall vehicle lifespan cost.

Conclusion

Whenever a breakthrough happens in welding technologies, we see it resonate in other industries as well. Not just in the one where it originated from. This welding technique works well and provides a unique manufacturing advantage when mass efficiency is necessary. Incremental mass reductions the aluminum provides, compared to steel parts, can improve heavy truck fuel economy too, but also in agriculture and vehicles and tools used there.

The applications of aluminum use are endless. Spot welding is one of the essential welding processes, and the ability to weld aluminum in a robust fashion with a reliable outcome is a welcome addition.