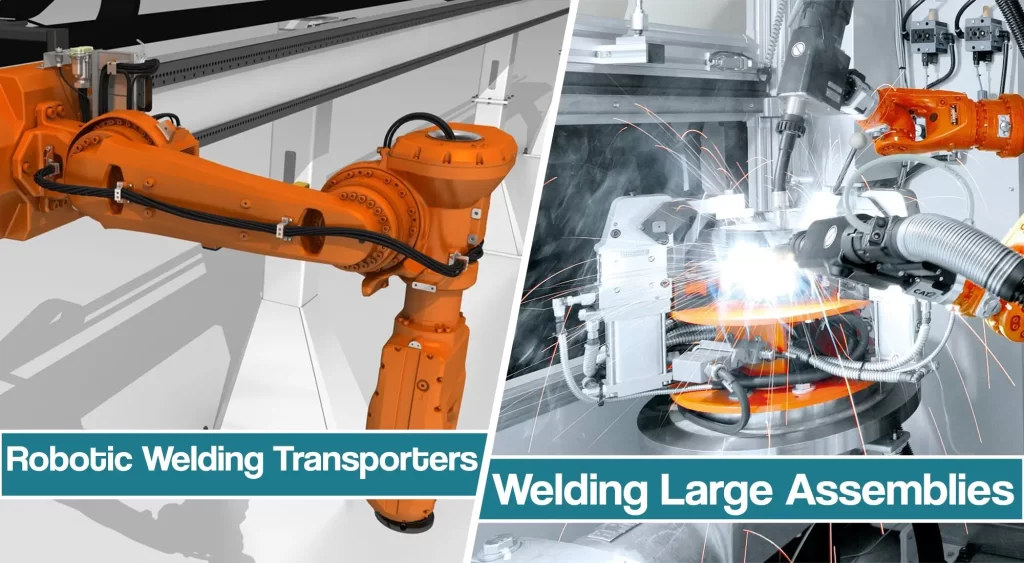

Robotic transporters are a vital part of automating the welding of extremely large, heavy parts. The maximum work radius of an extended-reach robot is approximately 9.84 ft.

If the parts you weld require more reach, you must find ways to move the robot to the part to provide optimal torch access to the welds. Various robot transporters are available, and each type lends itself to a particular workflow.

The question that emerges is how do you decide on the robotic transporter for large weldments? Whether your application best suited for a linear floor- or wall-mounted track, linear overhead gantry, or radial transport beam solution?

What Should You Consider When Choosing a Robotic Transporter for Large Weldments

First, let’s discuss the factors you should consider when choosing a robotic transporter. We will explain how cost, part size and configuration, part flow, facility structural safeguard and production considerations can affect your choice.

Cost of Robotic Transporter

Cost is always one of the primary factors you should consider when selecting a robot transporter configuration. A single robot costs less than a robot combined with a transporter.

However, a robot on a transporter can reduce the need for additional robots and maximize the use of an investment in welding automation equipment. Remember that multiple robots can be used together on some types of transporters to improve productivity.

In addition, some types of transporters take up more floor space, while others reduce floor space needs. Some robotic transporters have expensive installation requirements, while others have a facility and structural limitations or require special accommodations for part handling.

Robotic Part Size and Configuration

Besides costs, you should consider the physical dimensions — length, width, and depth — of all the parts that are to be welded robotically.

Do the parts need welds on all sides, on the outside only, or on the inside?

Also, consider whether are short, intermittent welds required, or does the part calls for continuous welds along its length? In the case of tubular parts, are the welds circumferential?

Part Flow In Production

Ask yourself if the parts flow in an inline production configuration, or do they enter the work cell from opposing sides? Are work stations parallel — next to each other — or opposing — on opposite sides of the robot?

Are the parts loaded by an overhead crane, forklift, or another method?

Structural Considerations

Structural considerations include floor reinforcement and the thickness of the floor’s concrete needed to support the robots and transporters, aisle width, ceiling height, support column spacing, overhead cranes, and lighting and ductwork that could cause interference with the robots or transport structures.

Safety Considerations

Worker safety is essential in any manufacturing plant. Therefore, safety equipment generally is designed to comply with the ANSI/RIA 15.06-1999 safety standard.

Welding cells require perimeter guarding with arc flash protection curtains, personnel gates with safety interlocks, and light curtains at operator workstations and any pass-through openings to the welding cell.

Transporters may require limiting devices to be used as interlocks for safeguarding the workspace.

Production Characteristics

You will need to determine whether multiple robots will be needed to meet the required production volumes.

Calculations need to be based on the number, length, and type of welds — that is, whether they are single or multi-pass — that are required per part.

Suppose these calculations show that multiple robots are required. In that case, you need to decide whether the robots need to share the same workspace, as in overlapping envelopes, or if separate, adjacent tracks will suffice.

Types of Robot Transporters

After determining the factors, you should know there are several types of robot transporters. In this section, we will explain how do they differ and how they can fit your needs.

Linear Floor Tracks Robot Transport

Usually, the least expensive robot transport option is linear floor tracks that allow the robot to reach welds on very long parts. Tracks can be as long as 98.4 ft. However, length is limited by the manipulator cables.

One or more robots can be mounted on a carriage that either index between two or more fixed positions along the track length or is servo-controlled by the robot controller.

Using a servo-controller allows continuous positioning of the robot anywhere along the track.

A servo-controlled track typically is less expensive if the robot needs to move to more than a few positions along the route.

Servo-controlled tracks also provide more programming flexibility. In a servo-controlled way, the robot can weld a continuous bead the length of the track. If coordinated motion control is included, the robot can be programmed to weld the part while turning.

A robot on a linear track can only access the part from a single side, so the width and depth of parts that can be processed are limited to the reach of the robot arm. However, robots often are mounted on risers on the track carriage to increase their elevation and depth of reach.

Floor tracks take up a significant amount of space, but parts can be processed on both sides of the track with an opposing workstation configuration.

Workflow is flexible. The cell layout can be configured to allow parts to enter from both sides of the track or to move in and out in a straight line from multiple — parallel — work stations on one side of a longer-length track.

Anti-collision software enables multiple carriages to travel on the same track without interference. Carriages also can be expanded to allow two robots to be mounted on a single platform.

Separate carriages are advantageous when relatively few welds are spread out along the length of the part. The robots can operate independently and work on opposite ends of the part or can be used to weld along the same seam simultaneously.

Two robots on a single carriage save the cost of an additional axis and are suitable for applications in which multiple welds are grouped. The carriage can be moved to a fixed position, and the robots can sequence the welds within their reach.

The carriage should be large and heavy enough to support a bulk wire drum for welding applications. That dramatically reduces wire feed issues. However, trying to feed the wire through the conduit in a cable tray is less reliable and generally requires an assist feeder at the drum. That increases system complexity, cost, and maintenance issues.

Safeguarding a linear track is not difficult if the manufacturer has provisions for mounting switches and cams to monitor the carriage position along the track. Such monitoring could include continuous position sensing or segmenting the travel into zones, depending on the risk assessment. Floor tracks require leveling when installed, but they work with modest concrete floor requirements and have minimum height requirements.

Wall-mounted Tracks In Robot Transport

Mounting a linear track in an elevated vertical position allows a robot to work from overhead. This configuration can give the transporter robot a wider reach and enable them to reach down into part cavities. This design is different from floor tracks, and support columns for wall-mounting add expense.

This can be especially useful in automated vehicle welding.

A robot on a wall-mounted track can only process parts directly in front of it, so this configuration lends itself to an inline part flow.

The wall-mounted track creates a narrower work cell because parts are processed from one side, and equipment can be located under the support structure. You must allow overhead clearance for the track and the rear of the robot on the carriage.

Welding electrode delivery is more difficult with a wall-mounted track because it is harder to mount a wire spool on the carriage on an elevated rail. However, as with floor tracks, multiple carriages can be located on a single wall-mounted rail.

Limiting devices can be mounted to the robot arm to mute safeguards while the robot is overhead and become active when it moves down into a workstation. As with floor tracks, safeguarding switches also can be added to monitor the carriage position.

Linear Gantries

Gantries extend the envelope of the robot beyond the reach of a wall-mounted track by suspending the robot overhead and adding additional axes.

The Y-axis of travel allows a broader part to be accessed by providing motion perpendicular to the length of travel. A vertical Z-axis enables a robot to reach deeper into part cavities. With the addition of gantry axes, a shorter-reach robot can be used to reduce the weight requirement for the gantry drives. Gantries with shorter axes can be supported from one side on a single rail. Larger span gantries utilize a bridge structure with supports on each side. Driving a bridge gantry requires special robot controller software to synchronize the motion of two independent motors to position each leg of the gantry.

Gantries can add a significant expense to a robot system, but they are one of the few ways to process substantial parts.

A part positioner is typically combined with a gantry to turn the part for robot access. Most robots feature software to allow the coordination of all axes — the robot, the base, and the positioner — to achieve long continuous welds or circumferential welds in a single pass.

A sufficient Z-axis stroke can allow the robot to weld the inside truck bodies, containers, or other box-like parts, while a longer Y-axis could enable the robot to work on the outside surfaces. But, of course, the longer the spans, the larger the required supporting structure, and the higher the cost.

Long cable length and cable management become an issue the longer the stroke of the robot transporter.

For gantry systems, it is not uncommon to mount the robot controller and process equipment to the gantry structure so that only primary power is supplied the length of the track and so that the robot and process cables are limited to the Y- and Z-axis stokes.

The other concern for a gantry system is overhead clearance, particularly for systems that use the Z-axis stroke.

Large parts usually require overhead cranes to load and unload. Users can add interlocks between the robot gantry and overhead crane to keep the crane out of the gantry area while the robot is operating or while the Z-stroke extends up in the air.

Multiple Track Configurations

Using two-floor tracks on either side of a large part may be less expensive than using a single robot on an overhead gantry. In addition, the multiple arcs provided by the dual-track configuration can enhance productivity.

Radial Gantries

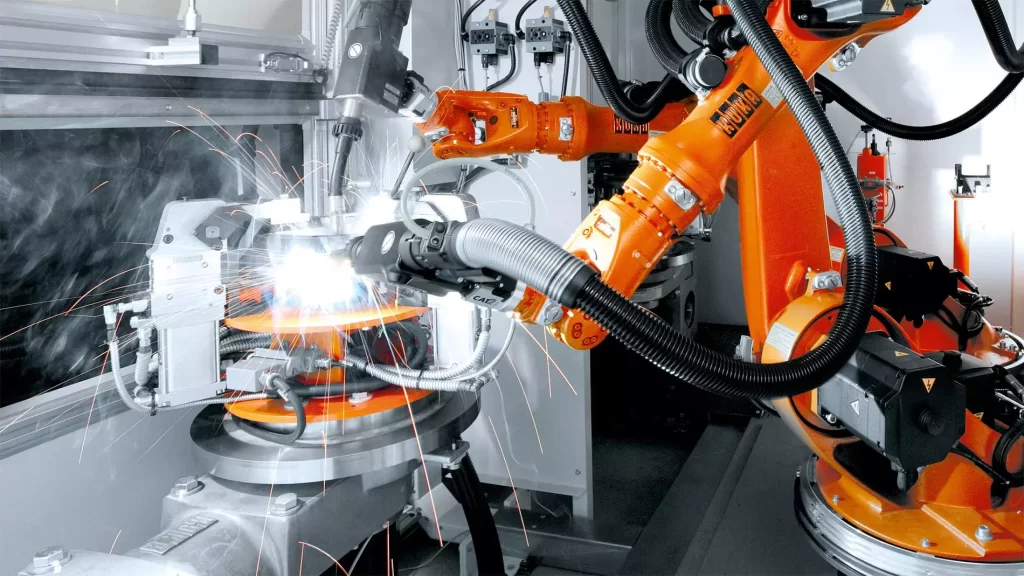

Radial gantries provide one of the most economical overhead robot transporter solutions. A rotary base is less expensive than a linear axis but has a fixed boom length. However, a single robot mounted on a two-meter to three-meter boom can expand its working volume by nearly ten times. Robots can be wall-mounted or ceiling-mounted on the end of the gantry boom.

Wall-mounted robots provide a deeper envelope, allowing robots to reach into part cavities or vertical access surfaces, such as the outside of a box.

Ceiling-mounted robots provide a broad, flat envelope suited to processing flat panels such as mower decks or truck sides. However, care needs to be taken with ceiling-mounted robots that wire feeders or cables do not hang below the arm, so they do not contact or snag the part or fixturing.

As with linear gantries, part positioners usually are combined with radial gantries to improve their flexibility. However, the orientation of the positioner in the work cell affects the robot’s access to the part.

Locating a headstock/tailstock positioner perpendicular to the boom allows the robot to process more extended parts using the length of the boom to move the robot closer to the headstock or tailstock.

The width of the part is limited to the robot’s reach — nearly double the distance for ceiling-mounted robots — and the part depth that can be accessed is limited. However, suppose the headstock/tailstock positioner is located, so it is in line with the gantry boom. In that case, the boom can be pivoted to either side of the positioner to allow the robot to access the part from each side, providing more depth.

The boom length is fixed, so the robot can only access parts limited in size to approximately twice the robot’s reach. In addition, booms can easily be moved out of the way to improve overhead crane access for loading and to unload large parts.

It is not possible to use multiple carriages with radial gantries, but it is possible to combine multiple gantries in the same work cell. Combining multiple gantries enlarges the part envelope that can be reached, and adds multiple arcs.

Similarly, radial gantries do not lend themselves to inline processing.

However, two work stations can be are located on either side of the base, 180 degrees apart, to expand the work envelope, and limiting devices can be integrated into the boom axis to interlock the booms, to provide safeguarding for either work station, and to prevent overhead crane intrusion into the active workstation. Also, more miniature robots can be mounted to a radial gantry to enhance their reach at a reduced cost.

Radial gantries also can be scaled up to include giant extended-reach robots.

Because a radial gantry supports the robot as a cantilevered load, it must be rigid and have a solid foundation.

Special foundation requirements, ballast or base plates may be needed to counteract the forces of a moving robot at the end of the boom.

Utilities normally are routed through the interior of the boom, and an assist feeder for welding wire can be mounted to the wire drum at the base of the structure. In addition, process equipment, such as nozzle cleaners, may be mounted on the boom near the robot.

Radial gantries often are used in applications in which short, intermittent welds or processing is done across the part. At the same time, linear tracks are often applied to applications requiring long, continuous weld seams.

While coordinated motion between the robot, boom, and positioner can achieve continuous welds, it is more common to “park” the boom in a stationary position and move the robot to weld joints within its reach.

Final Thoughts

In summary, the parts’ dimensions usually dictate the robot’s method of transporting. For example, in some cases, two radial gantries or floor tracks might be more economical than a single multi-axis gantry solution.

Using extended-reach robots on a single-axis transporter is less expensive than multi-axis transporter solutions. If multiple robots are used in the same workspace, then their programming and safeguarding must be addressed. It is most cost-effective to perform as much welding as possible on subassemblies in smaller cells and limit the welding time of more extensive components in large work cells to maximize their throughput.