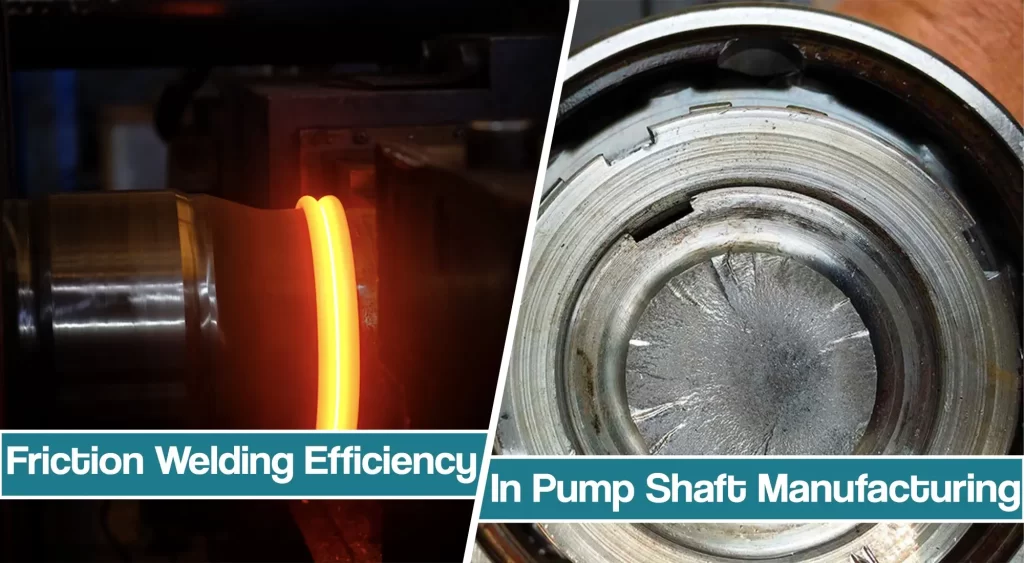

The challenges presented by material price versus performance in pump shaft manufacturing get tougher with each price increase for raw materials. Friction welding is a way to reduce costs and is a viable option for design engineering and new product development.

This article provides background on friction welding for pump shaft manufacturing.

We will cover the essential cost to performance and weld result factors, as well as the fundamentals of the welding process.

Fundamentals Of Friction Welding For Pump Shaft Manufacturing

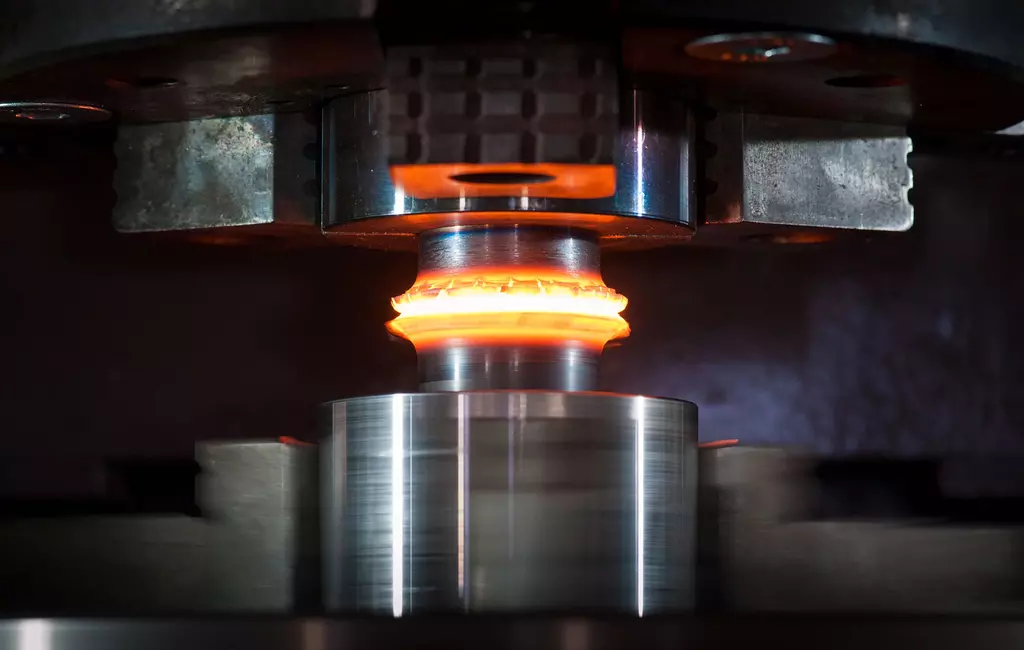

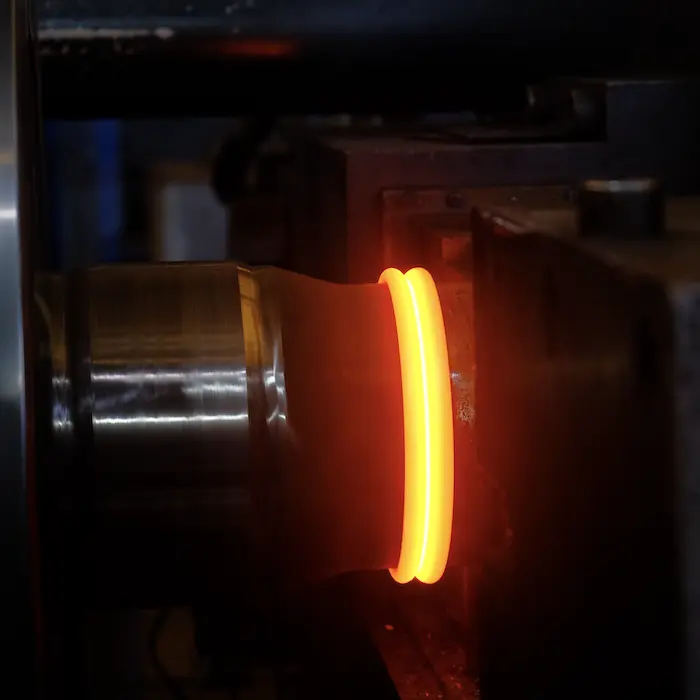

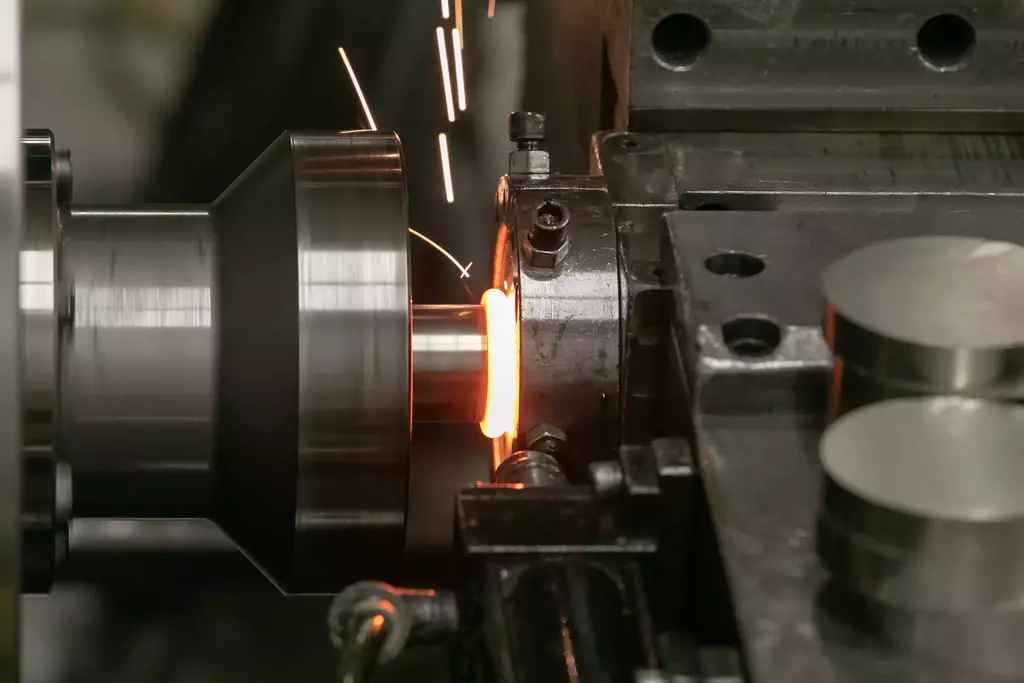

Although the friction welding process uses weld to define it, there is no resemblance to conventional welding. Primarily because filler material is not required. Instead, in friction welding, two components are rubbed at a controlled rotational speed.

This creates friction, and heat allows both pieces to reach a plastic state, and they are forged together into a bond. This process is used widely by prominent welding manufacturers in a variety of industries.

Friction welding involves the use of unique technology that incorporates state-of-the-art monitoring controls.

The process gives allows pump manufacturers to use composite shafts rather than one-piece shafts. Next, this helps the manufacturers select the best materials to suit an application easily. As a result, it also reduces concern for raw material costs. In essence, the friction welding process creates a better balance when selecting optimum material without the heavy price tag in the mind.

Cost versus performance criteria can be realized without sacrificing performance. This includes resistance to abrasion or corrosion, mechanical strength for operating loads, and FDA-mandated sanitary characteristics.

With costs of $3 to $34 per pound for commonly used stainless steels and high nickel alloys, using lower-cost materials for 60 percent of a shaft can provide significant savings in shaft manufacturing.

Dry End Versus Wet End Shaft Considerations

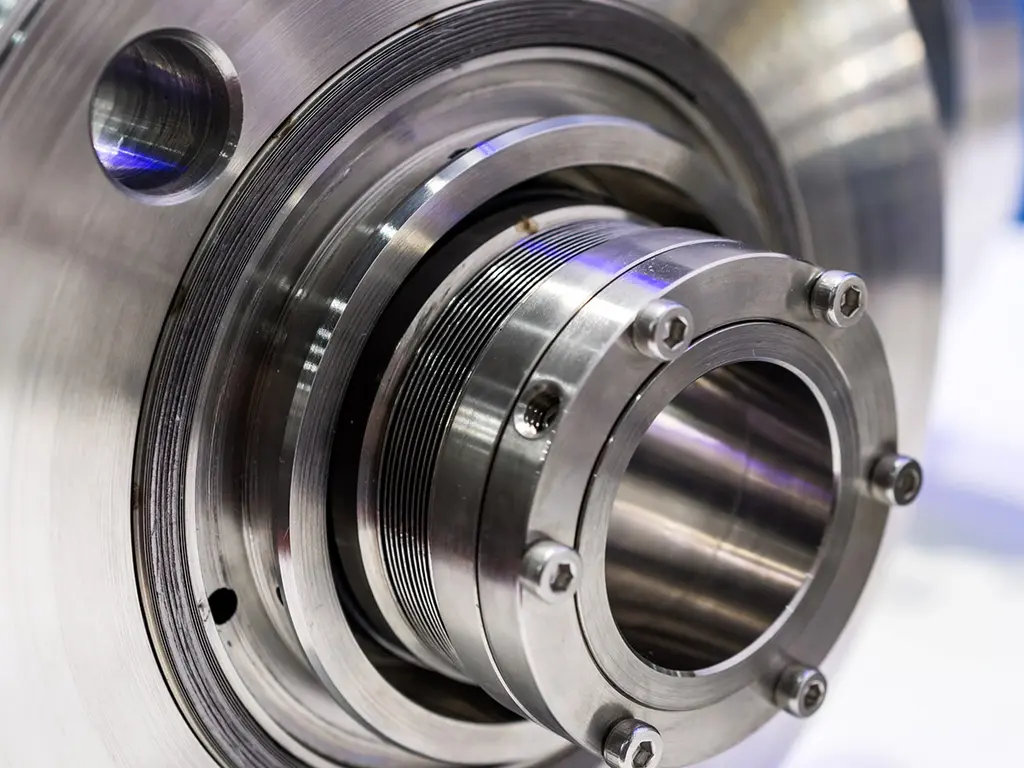

To understand how to cut costs, you should know pump shafts have two distinct ends: a dry end and a wet end. The dry end is sealed and encased, usually in oil, within the pump’s housing. The wet end, which usually is outside the pump enclosure, comes into contact with the application.

As the dry end has a less critical role in most applications, you can use less costly materials such as low carbon steels for this part of shafts. However, sufficient strength for the application should be maintained. Conversely, the wet end of the shaft is where “the rubber meets the road” due to its direct contact with the external, ambient conditions of the application.

This is where it gets serious, and where more costly, exotic high nickel alloys and high strength stainless steels are often required. You can save money by making composite shafts with, generally, two-thirds of the shaft’s less critical dry end made with materials, such as carbon steel.

Considering the challenges of price volatility and surcharges in the prices for nickel-based materials, which often exceed the material’s base cost, these savings can be substantial for manufacturers. They also promote significant cost and profit stability for the end product. With a proper selection of materials for the dry and wet end of the pump shaft, the strength properties of the original material typically can be met, with cost savings.

State-of-the-art control via monitoring and visual graphing during the friction weld process and post-weld ultrasonic inspection procedures ensure consistent weld joint integrity. Production controls monitor RPM, axial load, and displacement of material during welding.

Finished parts can be shipped to accredited laboratories for metallurgical evaluation and/or a variety of mechanical tests. That way, you can inspect torsion, tensile, and normal bend tests over designated radii for specific applications. Parts typically are rated for loads that exceed the intended applications.

The integrity of Friction Welding Joints

Due to the possibility of saving money, experts have performed an extensive analysis of friction welded joints. Comparing friction welded to conventional welded joints, experts state that the heat-affected zone (HAZ) is less extensive and has a narrower width than the heat-affected zone of a conventional weld that incorporates a filler material.

Heat-affected zone mechanical properties are similar to the base metal but, depending upon the temperature achieved during welding, the cooling rate, and the post-weld thermal treatment, all three can change the weld properties. If all are controlled correctly, welds will have the necessary integrity, which is crucial.

The successful friction weld will be free of porosity, and there are no fusion or oxide inclusions. On rare occasions, very fine oxides can be dispersed through the center of the joint.

Crucial Material Considerations

On the shaft wet side, a variety of stainless steel and nickel-based alloys typically are used to meet the requirements of the application. For example, 304 stainless steel, 316 stainless steel, or 17-4 PH stainless steel can be friction welded to produce the wet side of a pump shaft. These offer higher mechanical properties and to provide a balance between strength and corrosion resistance.

On the dry side of the pump shaft, options are virtually endless. Manufacturers can use medium and low carbon steel or stainless steel for corrosive resistance if it is needed.

Even with stainless on the dry end, cost reductions often are realized. When the weld integrity is concerned, the 1100 series and 1200 series carbon steel with re-phosphatized and re-sulfurized content that offer enhanced machinability, should be avoided. These materials have increased amounts of sulfur or lead, which can create issues in the friction welding process.

A Broad Range of Friction Welding Options

Friction welding provides more options for the production of pump shafts beyond the cost of materials. In designing projects for pump applications, manufacturers can use material with properties that are wider in strength and corrosion resistance.

On the dry end, specific wear resistance, longevity in the length of service and related fatigue, and the loads are all important factors to be considered when choosing materials. Manufacturability benefits also can be realized with friction welding.

Shafts can be designed for optimum manufacturability and machinability, and significant reductions in machining costs can be achieved. With optimized materials, costs for cutting tools can be reduced, machines can be run at faster feeds and speeds, and machine tool uptime and output can be increased. Those can combine to provide as much as a 15 percent savings while, at the same time, giving manufacturers as much as 20 percent more capacity on machine tools and machining cells.

Friction Welding and Cost Savings

Based upon the requirements of an application, as much as a 60 percent savings on raw material costs can be utilized with friction welding. That saving includes the cost of the friction weld. For example, a 2.5-in. diameter, high-strength alloy shaft made of a material that weighs as much as 17 lbs. per linear foot, would weigh about 51 lbs. for a 3-ft shaft. At $5.00 per pound, this shaft would be about $255.

If friction welding is used to replace two-thirds – 2 ft – of the shaft’s dry end with lower cost, carbon steel material at a cost of 60 cents per pound, this shaft would cost around $105, a savings of 58 percent. Although friction welding has been around for more than 50 years, it continues to be one of manufacturing’s best-kept secrets.

For the cost challenges that are presented by high-strength, nickel-based materials, the ability of friction welding to replace large percentages of such costly materials while maintaining the strength and structural integrity that are required for any application provides a strong incentive for cost-conscious pump manufacturers.