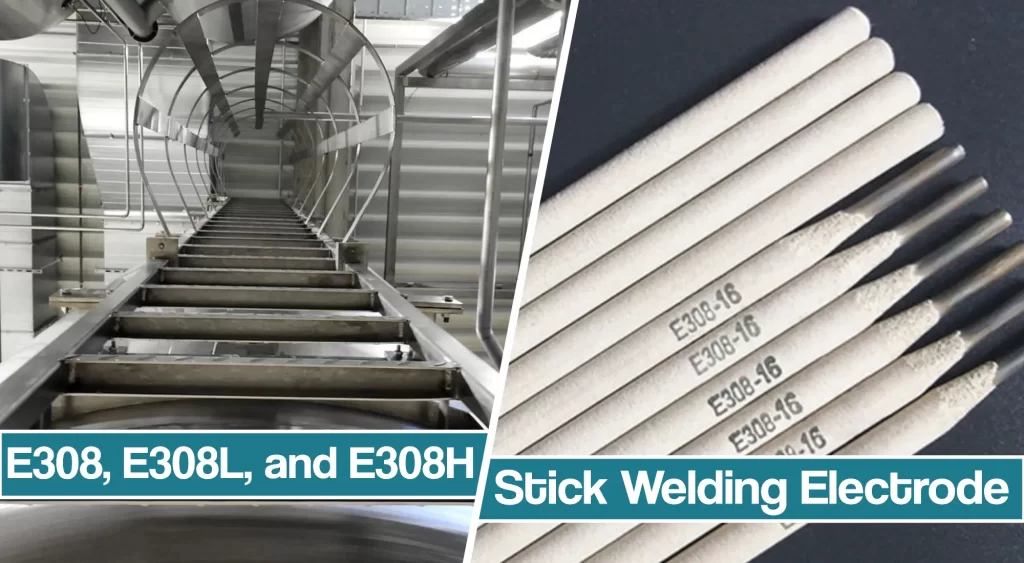

The E308 stainless steel stick welding electrode is one of the most commonly used electrodes for stick welding stainless steel.

It’s used to weld austenitic stainless steel and comes in two additional variations, the “L” and “H” designations, which we’ll explain soon.

In this article, you’ll learn what stainless steel types the E308 electrode is designed for, which designation to choose, and how to determine the polarity. So, let’s start.

E308 Electrode Stainless Steel Type

American Welding Society (AWS) classifies the E308 for welding austenitic types of stainless steel. This is the most common stainless steel type, but there are also martensitic, ferritic, duplex, and precipitation-hardening types of stainless steel. The E308 electrode cannot be used to weld any of those.

E308 stick welding electrodes are used for welding the following grades of austenitic stainless steel 201, 202, 301, 302, 304, 304N, 305, and 308.

E308 vs. E308L vs. E308H – What’s the Difference?

The “308” stands for a particular stainless steel type, and this steel is used to make electrodes for welding austenitic alloys we outlined above.

The “H” and “L” designators indicate a specific composition of the electrode. More specifically, they refer to the carbon percentage in the electrode, with “H” electrodes in the high end of the electrode’s carbon range and “L” electrodes in the low end.

There is a significant difference in the application of E308L and E308H. Carbon content in the weld joint can make or break the success of the weld. Literally.

However, if you find that the E308 type of stainless steel stick welding electrodes are not the best fit for your application, please refer to our stick welding electrode calculator. There, you can find all stick electrodes and see which one best suits your needs.

E308L Stick Electrode Applications

The E308L stick electrode can’t have more than 0.04% carbon content in its overall composition. You can also see the term “extra-low carbon” or “ELC” used to designate these electrodes.

Since stainless steel is highly sensitive to carbide precipitation in the heat-affected zone (“HAZ”), which leads to losing corrosion resistance, the E308L is a preferred electrode where preserving corrosion resistance is paramount.

Since the electrode itself inputs a minimal amount of carbon in the joint, the chances of carbon concentrating in the joint area are lessened. As a result, the HAZ is less likely to corrode.

The E308L electrode is used to weld parts exposed to severe corrosive conditions. But the E308L also helps less experienced welders avoid carbide precipitation.

E308H Stick Electrode Applications

The E308H stainless steel electrode has a higher carbon content with a range of 0.04% and 0.08%. The high carbon content may worsen your odds of avoiding corrosion resistance. However, higher carbon content improves tensile and creep strengths at higher temperatures.

The industrial equipment that’s exposed to extremely high temperatures is welded with the E308H stainless steel electrode.

But, hobbyists who do DIY projects like furnaces, grill bars, etc. can also utilize the E308H. Just make sure to avoid high heat concentration in the weld metal. Since the electrode already inputs more carbon into the joint, you don’t want to let the carbon concentrate and create a corrosion point.

Note that electrodes are often dual classified. So, they can be classified as E308 / E308L or as E308 / E308H. The 308 Grade has a broad carbon range, so if a particular electrode’s carbon content falls within the tighter L or H carbon level requirements, it also meets the more general 308 requirements.

However, you will never see an E308L / E308H classified electrode because one electrode can’t have a carbon content that falls within the low and the high end of the carbon range. Note also that the “H” and “L” carbon designators can apply to other types of austenitic stainless steels besides E308. Some examples include E309H, E309L, E310H, E316H, E316L, etc.

Stainless Steel Electrodes Polarity

All stainless steel stick electrodes have coatings designated with four numbers: 15, 16, 17, and 26.

The coating number is a part of the electrode name. For example the E308-15, E308-16, and E308-17. The coating type determines the welding polarity and position.

- A “15” electrode has a lime-based flux coating. It is designed for DC+ polarity only. These have a lighter slag than the other types and are used for all position welding, with some electrodes of this type used primarily for vertical down welding.

- A “16” electrode has titania- or rutile-based flux coating and can be used with both DC and AC polarity. Electrode sizes of 5/32 in. (4.0 mm) and smaller are often used in all welding positions. There is also a “26” classification, which is the same as a “16” type, but it provides higher deposition and is limited to the flat and horizontal positions.

- A “17” electrode is coated with a silica-titania type coating, which is a modification of a 16 layer — some of the titania is replaced with silica. The 17-type electrode can be used with both DC and AC polarity. Additional silicon in the coating functions as a wetting agent, which increases puddle fluidity. This is particularly helpful with stainless steel because it tends to have a more sluggish weld bead than carbon steel. And, 17-type electrodes produce a flatter bead profile than other electrode types and are used to weld in a flat and horizontal position.

Conclusion

The E308 electrode is your standard go-to rod for welding most austenitic stainless steel. Stick welding stainless works quite well — it provides similar results as MIG welding stainless steel. But, it does take some practice because the stick welding process is generally more challenging.

Be extra careful when removing slag off of stainless steel welds. The slag has a nasty habit of ending up in your eye. So, either keep the welding hood on or use safety glasses.